Skip to content

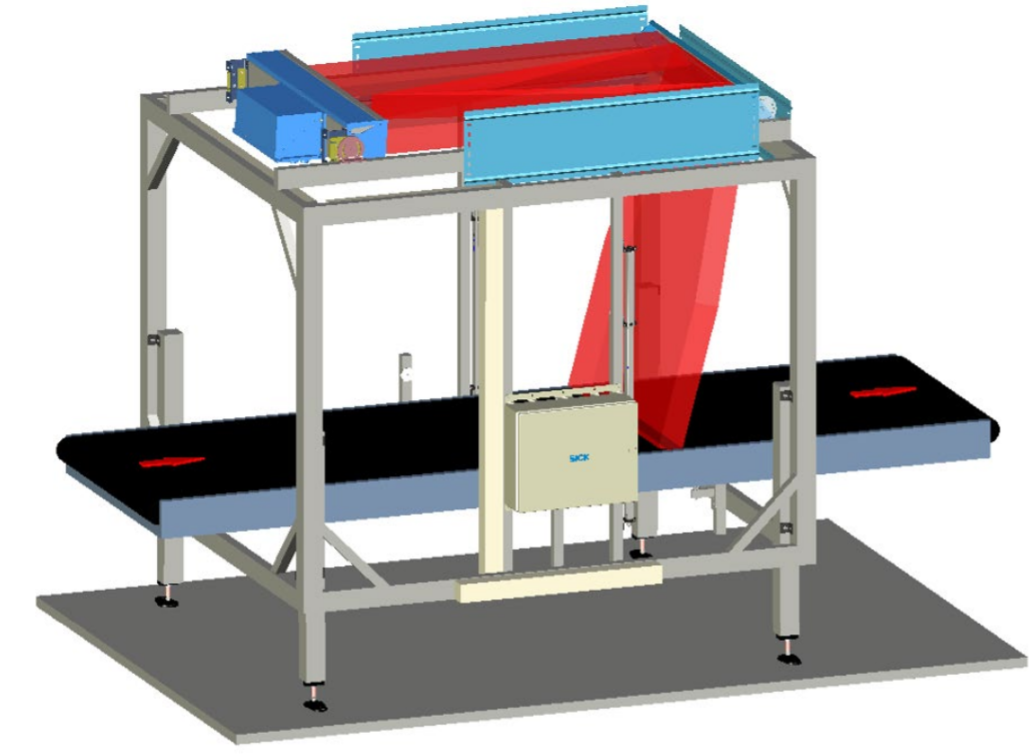

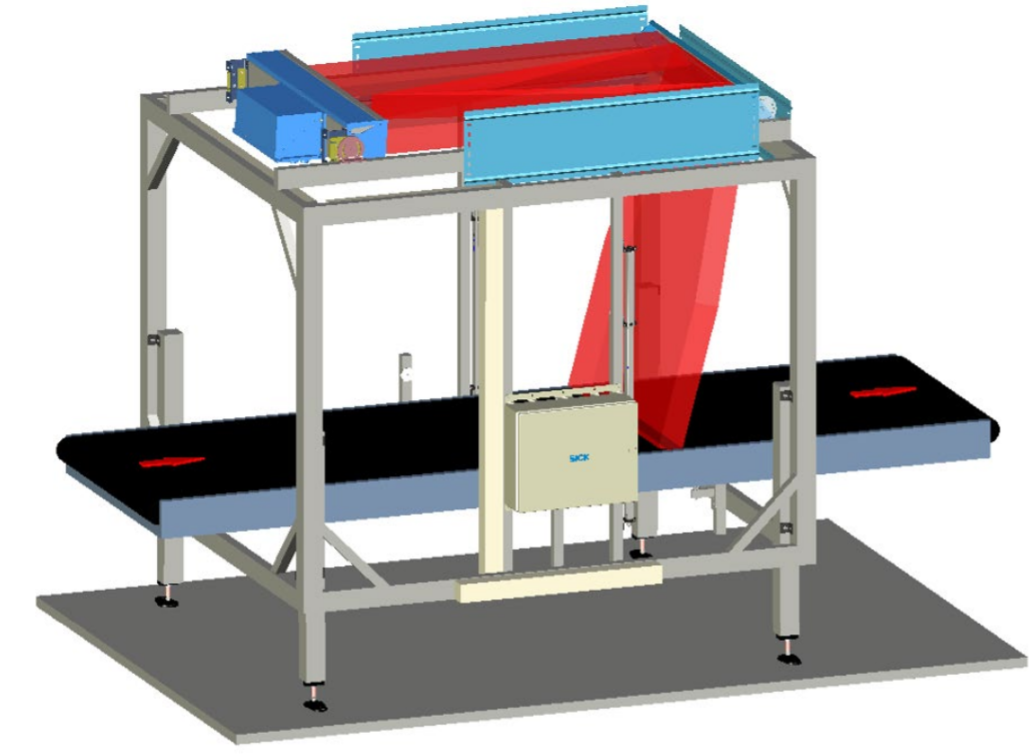

AUMI company has consulted and installed the code reading system on the goods using the ICR890 SICK code reading camera in Vietnam

Device details:

The features of ICR890 system SICK

- Read field 1,400 mm … 3,000 mm

- Optical focus: Dynamic focus control

- Type code: 1D codes, 2D codes, Stacked, plain text

- Field of view: 1,175 mm (170 dpi)

- Housing material: Aluminum die cast

- Housing color: Light blue (RAL 5012)

- Speed 4.8 m/s (100 lpi)

- Interface: Ethernet/ Serial/ CAN bus

- Ambient temperature: 0 °C … +50 °C

- Weight: 13.5 kg

wpDiscuz