Hai Phong Vicem Cement Company, formerly known as Hai Phong Cement Factory, started construction by the French on December 25, 1899 on the land of confluence of Cam River and Ha Ly Canal, was the first cement factory in Vietnam and Indochina, with the traditional “Dragon” brand that has long been imprinted in the subconsciousness of every Vietnamese. The Company’s main products are Portland cement mixed with PCB30, PCB40 and other special cements on order.

Company Name: Vicem Hai Phong Cement Company Limited (hereinafter referred to as Vicem Hai Phong Cement Company)

Address: Trang Kenh – Minh Duc – Thuy Nguyen – Hai Phong

Aumi Company has completed the project of installing TQT emissions at Hai Phong Cement Plant, Aumi has provided a synchronous solution from automatic continuous data sampling to reporting to users and Department of Natural Resources and Environment.

Project details:

- Number of stations: 04

- Parameters: Flow, dust, temperature, NOx, SO2, O2

- Location: Hai Phong Cement Factory – Trang Kenh – Minh Duc – Thuy Nguyen – Hai Phong

- Investor: Vicem Hai Phong Cement Co., Ltd

Now that the system has been put into operation, the system after installation ensures the monitored parameters, sampling location, automatic emission monitoring device and accessory system, as well as ensuring the safety of the system. quality assurance and quality control (QA/QC) according to the provisions of Circular 31/2016/TT-BTNMT.

The automatic emission monitoring station of the cement industry is a system consisting of hardware and software for continuous automatic measurement of pollutant components in the exhaust gas, storing data on the spot, on software, and at the same time being recorded and transmitted to the Department of Natural Resources and Environment according to regulations. The automatic emission monitoring system must operate stably, be tested and calibrated according to regulations and must ensure connection technical requirements to transmit data directly to the Department of Natural Resources and Environment.

Automatic emission monitoring devices used at the factory are the latest advanced Hotwet devices from Sick. The emissions monitoring system at Hai Phong cement plant installed by Aumi operates under a fully automatic process, the station will record the parameters of emissions quality (Flow, dust, temperature, NOx, SO2), O2) and transmitted to the Data Center to help control the quality of waste sources.

The emission monitoring equipment provided by Aumi Company to Hai Phong Cement Factory, including:

I. Monitoring devices:

- Emissions temperature and flow meter – Model: Flowsic 100 – Sick – Germany

- Dust measurement equipment of emissions for chimneys – Model: Dusthunter T – Sick – Germany

- Emissions analyzer (CO, O2, SO2, NOx) – Model: MCS100 HW – Sick – Germany

II. Data transmission system and monitoring cabinet system

- The set of equipment for receiving and transmitting data with Hai Phong Department of Natural Resources and Environment and the operator

- Equipment station house

- Equipment monitoring cabinet

- Standard emission tank – Messer

- Installation accessories

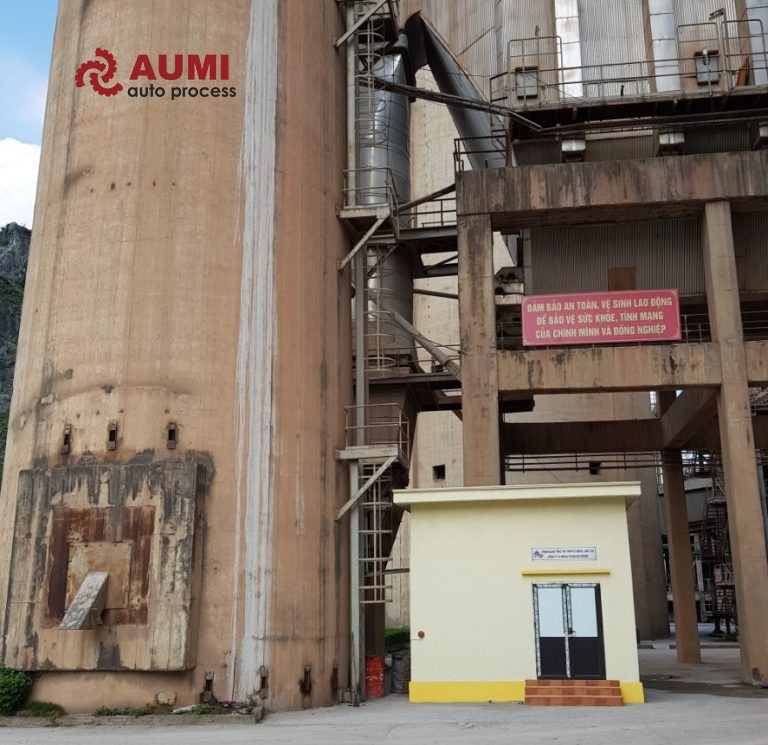

III. Project pictures:

Figure 1: House of emission monitoring station

Figure 2: Hot-wet technology gas analyzer

Figure 3: Exhaust gas analyzer

Figure 4: Measuring device on cooler stack

Figure 5: Measuring device on coal stack