| Product | Part No. | Communication Interface detail | Enclosure rating | Number of steps per revolution |

| ACM60B-S1KE13x06 | 6045312 | Current | IP65, IP67 | 10485 |

| ACM60B-S1LE13x06 | 6045313 | Voltage | IP65, IP67 | 13107 |

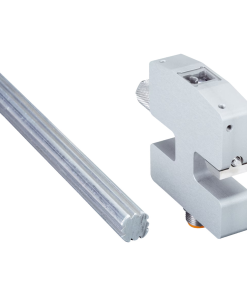

Absolute encoders ACM60

- The ACM60 (multiturn) encoder family has an analog interface with a maximum overall resolution of up to 13107 steps.

- A current signal of 4-20 mA or a voltage signal of 0-10 V is output depending on the device version.

- Programming via keypad on the encoder

- IP68 protection class

- Operating temperature: –30 °C to +80 °C

Categories: Sick, Adsolute encoders, Encoder

Tags: Adsolute encoders, Encoder, ACM60

At a glance:

- The ACM60 (multiturn) encoder family has an analog interface with a maximum overall resolution of up to 13107 steps.

- Using the teach-in function on the membrane keyboard, the measuring range can be intuitively programmed directly on the device with just a few clicks.

- A current signal of 4-20 mA or a voltage signal of 0-10 V is output depending on the device version.

- Intuitive configuration of the measuring range directly on the device using membrane keyboard (teach-in function) saves time and requires no special expertise.

- The compact size (including M12 connection technology) allows the encoder to be used in confined spaces and thus provides greater freedom for development and machine design.

- The analog interfaces (current/voltage) offer a low-cost solution for detecting the position and path, and thereby help to reduce overall system costs.

Features:

- Servo flange

- Radial connector connection

- Analog interface 4 to 20 mA or 0 to 10 V

- Programming via keypad on the encoder

- IP68 protection class

- Operating temperature: –30 °C to +80 °C

Related products

SALE

- Sensor principle: Inductive

- Response range of up to 20 mm

- Direct connection to the safe control solution eliminates any additional wiring and reduces installation time

- Fast diagnostics via LED status indicator

- Just one safety switch in conjunction with a suitable safety module makes it possible to solve applications up to PL e and Cat. 4 (EN ISO 13849)

SALE

Motion control sensors

- Inclination measurement in two axes without mutual interference

- Reliable output signal thanks to configurable digital filter

- High resolution (0.01°) and accuracy (±0.1° typ.)

- Programmable with the PGT-12-Pro

SALE

- Extremely small housing saves installation space, thereby increasing efficiency of the system

- Reduced storage costs, flexible machine design and easier service

- Yellow LED as optical adjustment indicator and output state display

- Green LED acts as a status indicator

- IO-Link and automation functions

SALE

- The smart solution for challenging detection tasks

- With the WLL80 opto-electronic fiber optic amplifier, SICK is creating a new generation of amplifiers for the flexible integration of fiber optics in confined spaces.

- The intelligent WLL80 features IO-Link and can make processes even more efficient with various Smart Tasks. Thanks to IP54, it is protected from dust and spray water during operation. Continuous threshold adaptation ensures good performance in the long term with minimal maintenance requirements.

- In addition to a fast response time and high detection range, it is characterized by flexible and user-friendly parameterization via the OLED display or IO-Link. Whether as a single or bus version, the WLL80 is suitable for a wide range of applications thanks to its extensive fiber optics portfolio.

SALE

- Special housing for rapid mounting and adjustment

- Dual sensors detect double columns of marks

- Tight dual-sensor mounting ability

- Detects 1-18 marks of different colors