Magnetic sensors

- Space-saving installation due to small design.

- Large operating ranges with reliable switching increase throughput.

- Electrical configuration: DC 3-wire.

- Enclosure rating: IP 67.

- Temperature range: –25 °C to +75 °C.

Magnetic sensors

- NAMUR version ensures safe function in explosion-hazardous areas.

- Types: M12 to M18.

- Sensing range: up to 120 mm.

- Enclosure rating: IP 67.

- Temperature range: –25 °C to +70 °C.

Sick

- High contrast and color resolution for best possible performance, even when detecting complex materials.

- Diagnostics, visualization, and simple format change via IO-Link.

- Space-saving due to compact design.

- Switching frequency: up to 70 kHz, jitter: 3 µs.

- IO-Link and flexible sensor settings.

Sick

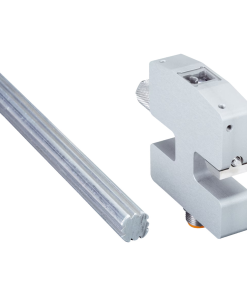

- Rugged and accurate, insensitive to ambient light, contamination or surface defects.

- Small curve radii of up to 0.5 m possible.

- Low installation costs.

- Measurement accuracy: ± 1 mm.

- CANopen, RS-485 or IO-Link.

- Attractive alternative to expensive color measurement solutions thanks to the output of color values and high color resolution.

- Quick and easy commissioning.

- Display of color values on the sensor display.

- Output of color values (L*a*b/RGB) and color similarity.

- Full color TFT display.

Array sensors

- Higher reliability and more stable processes thanks to teach-in of contrast edges.

- IO-Link and the SOPAS ET software ensure easy configuration.

- Full color TFT display.

- Sensing distance of 25 mm or 100 mm.

- Repeatability of up to 30 µm.

Sick

- Stable aluminum housing for use in harsh industrial environments

- Easy to access data from the PLC via IO-Link

- Fast response time: 100 μs

- PNP and NPN switching output

- Light/dark switching function

- Stable aluminum housing with IP 65 enclosure rating

- For universal use with easy adjustment

- Filters ensure that background luminescence is reliably suppressed, ensuring greater process reliability

- Tough metal housing

- Simple sensitivity adjustment in 8 stages

- Fiber-optic cable connection (with 20 mm lens)

Sick

- Space-saving installation thanks to the slim housing

- High process accuracy because belt flutter is minimized when installed on the dispensing edge

- Detects label separations of 1 mm and greater

- Intelligent sensor with integrated IO-Link interface

Contrast sensor

- Special housing for rapid mounting and adjustment

- Dual sensors detect double columns of marks

- Tight dual-sensor mounting ability

- Detects 1-18 marks of different colors

Sick

- Plug-and-play fork sensors – connect and get started.

- The WFM fork sensors are extremely quick and easy to mount and commission thanks to plug and play.

- Their yellow receive indicator can be seen all the way round, providing optimum feedback on the switching behavior of the WFM. Since the sender and receiver are integrated within the same housing, there is no need for any complex alignment work, allowing detection tasks to be prepared and completed quickly and easily.

- WFM have a rugged aluminum housing and are available in five different designs with fork widths ranging from 30 mm to 180 mm and fork depths of between 40 mm and 120 mm.

- SICK's fork sensors are suited to numerous applications, such as detecting parts in production processes, checking whether various objects are present, or intralogistic processes.

- Safe object detection at high machine speeds

- The KTL180 reliably detects contrast differences even at high machine speeds.

- Thanks to its 31.2 kHz switching frequency, a high grayscale resolution and manual switching threshold adjustment, the KTL180 makes for safe object detection.

- The response time of 16 µs ensures stable and accurate detection of contrast differences, for example with print marks, even for high-gloss materials. The sensor can be quickly adjusted to the respective application with the 7-segment display and easy menu guidance.

- Various teach-in processes as well as an integrated job save increase the flexibility during commissioning in a large range of applications with very high process stability.