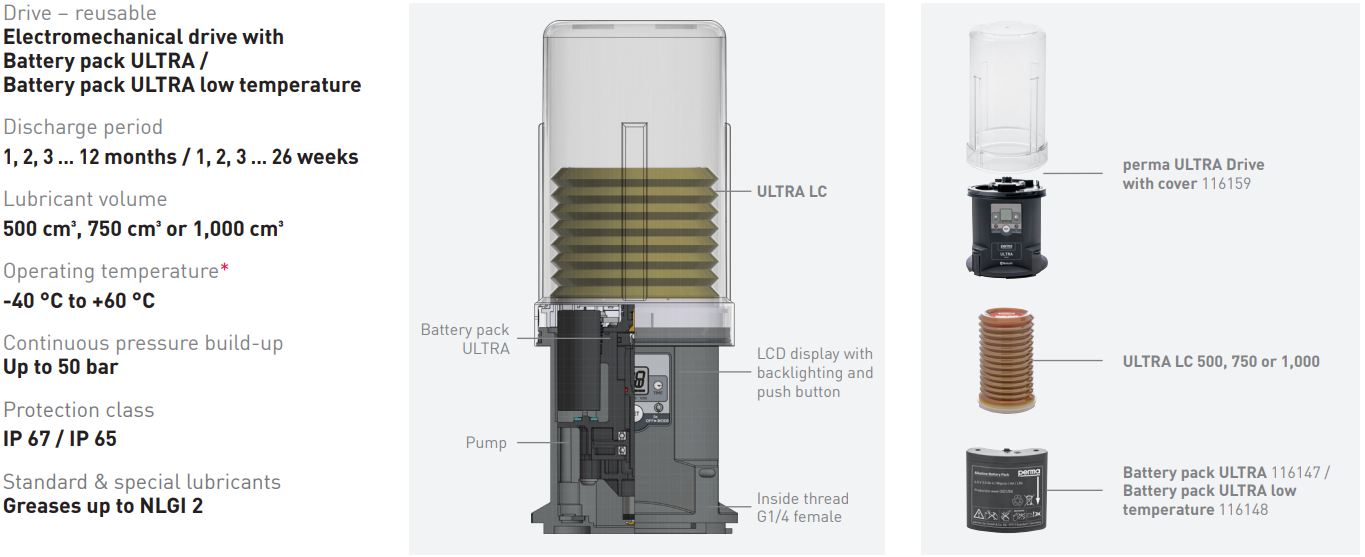

- Drive: Electromechanical

- Power supply: Battery pack ULTRA 6.0 V

- Housing: Plastic

- Discharge period: 1, 2, 3, …, 12 months | 1, 2, 3, …, 26 weeks

- Lubricant volume: 500 cm³, 750 cm³, 1000 cm³

- Operating temperature: -20 °C to +60 °C (Alkaline) | -40 °C to +60 °C (Lithium)

- Pressure build-up: Up to 50 bar

- Protection class: IP 67 / IP 65

- Lubricants: Grease up to NLGI 2

- Max. tube lengths: 20.00 m

- CE: ✔