Description:

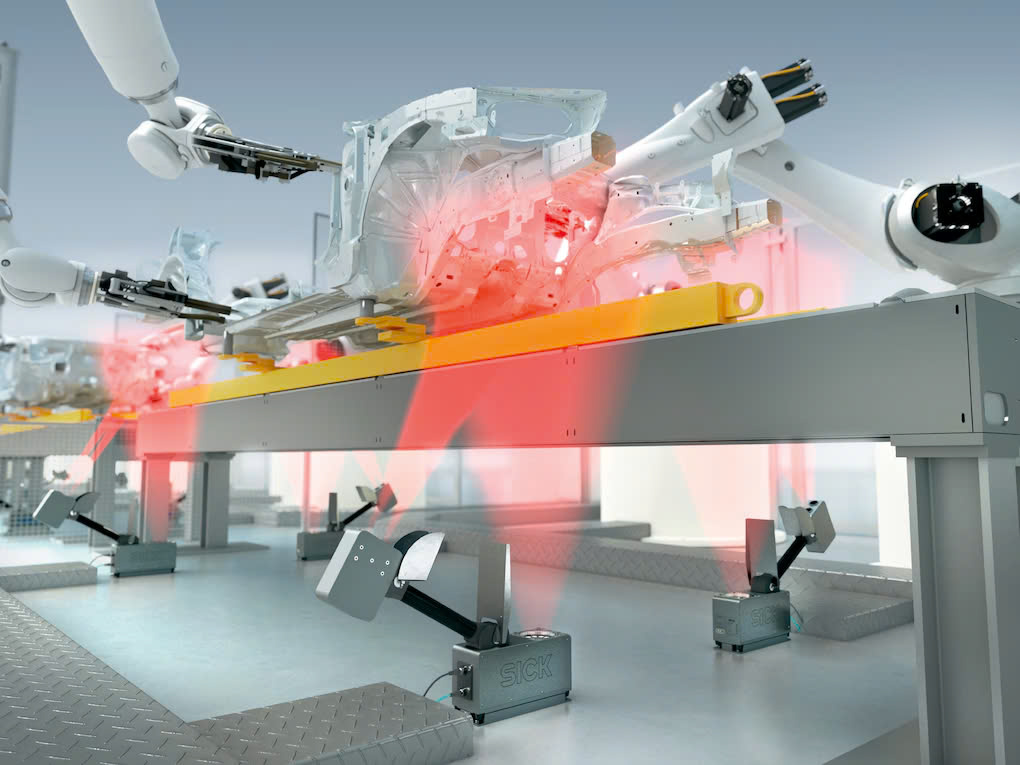

- In all areas of industry, especially automotive, factories always focus on improving and developing operating processes to be as optimal and time-saving as possible, one way to do that is making a fully automated production line and BPS from SICK can do that.

- The robot guidance Body Position System (BPS) is a contactless camera-based system for the precise localization of vehicle bodies. The system measures reference points (RPS) on vehicle bodies and transmits them to the robot. Based on the collected data, the robot then performs various applications according to the actual vehicle position. BPS is a technologically advanced replacement for the mechanical devices currently used in skid carrier-based automotive manufacturing. This enables the fully automated production of any number of different vehicle types in just one production line.

Applications in fields:

- Robot-guided welding, gluing, material handling, and assembly applications in automotive industry.

Technical details:

- The system determines the x, y, z coordinates of reference points (RPS)

- Flexible solution fits almost any robot cell design

- Stand-alone solution – no need for external IPC

- Web-user interface

- Robust housing protects components even in harsh environments

- Optional electrical cabinet with touch screen display

Benefits for users:

- Increased production flexibility – more vehicle types can be produced on the same line

- Reduced cycle time per vehicle body for faster production

- Easy installation, lower operating costs and less maintenance than mechanical solutions

- Low maintenance expense and reduced downtime by minimizing mechanical wear and tear on car carriers

- Integrated redundancy allows system operation even if one camera module is nonfunctional

- The compactness of the system allows installation even in challenging environments.

- One step closer to a green factory – significant energy savings and less mechanical wear