SALE

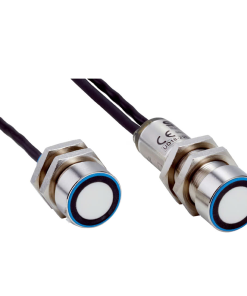

- Maximum productivity and quality thanks to reliable material transportation monitoring.

- Rapid commissioning thanks to plug-and-play plus a range of sensitivity levels to choose from.

- Variable mounting distance.

- LEDs visible from any direction.

- Immune to dirt, dust, and humidity.

SALE

- Non-contact measurement improves quality inspection during production

- High visibility LC display enables simple, cost-effective setup

- Numerous measuring ranges from 24 mm ... 26 mm to 300 mm ... 700 mm

- Maximum measurement accuracy and frequency

- Glass thickness measurement with just one sensor head

SALE

- Distance measurement using the chromatic confocal method regardless of surface and material changes

- Saves space due to the compact dimensions of the control unit and sensor heads

- Scanning frequency: up to 10 kHz

- Scanning range: 0.6 mm, 4 mm, 10 mm

- Resolving power: optionally up to 25 nm, 180 nm or 400 nm

SALE

- Quality optimization due to thickness measurement with micrometer precision

- Reliable process control of web material thanks to exact edge position determination

- Miniature metal housing

- Integrated LED alignment aid

- High-resolution CMOS receiver with high repeatability

SALE

Linear measurement sensors

- High travel speed linked to precise positioning increases system efficiency and improves throughput.

- The large temperature range from –30°C to +60°C offers reliable use in many applications.

- Adjustable resolution as low as 0.1 mm.

- Precise positioning up to 10,000 m

- Wide range of interfaces: SSI, RS-422, RS-485, and CANopen.

SALE

Linear measurement sensors

- High travel speed linked to precise positioning increases system efficiency and improves throughput.

- The large temperature range from –30°C to +60°C offers reliable use in many applications.

- Highly accurate camera-based bar code positioning system.

- Adjustable resolution as low as 0.1 mm.

- Precise positioning up to 10,000 m.

- Compact, extremely rugged magnesium housing.

SALE

- Very good measurement performance, even with quick or rotating objects thanks to high measuring frequency.

- Sensor is easy to configure via a web server interface.

- Reliable edge detection thanks to innovative analysis algorithm.

- Measuring frequency up to 80 kHz.

- Ethernet interface with TCP/IP protocol directly in the sensor head.

SALE

- A wide measuring range and a compact housing increase the number of possible applications.

- Three switching modes provide a simple solution for demanding applications.

- Measuring range up to 10 m on black targets and up to 30 m on white targets, compact dimensions.

- Output rate up to 3,000/s.

- Repeatability: 0.5 mm to 5 mm.

SALE

- Measuring a 2D profile with just one sensor saves on hardware and installation costs

- Real-time visualization of the measurement results via the integrated LC display

- Measure complex profiles with just one laser line

- Commissioning via software or integrated display with operating elements

- High-quality CMOS receiver unit

SALE

- Mini housing allows for quick and easy integration, even in the most confined spaces

- Integrated temperature compensation ensures high measurement accuracy at all times for optimum process quality

- Teach-in button

- Precise background suppression

- Immune to dirt, dust, humidity, and fog

SALE

- Small, rugged metal housing and SpeedCon™ compatible connectors ensure hassle-free installation – even in confined spaces

- Numerous accessories allow flexible use and guarantee high operation functionality

- Measuring range up to 300 m (dependent on type)

- Elongated holes for zero point adjustment when replacing devices