SALE

Linear encoders

- Simple integration of the system thanks to the HIPERFACE® or HIPERFACE DSL® interface

- STL70-2 certified according to SIL2 and PL d (HIPERFACE® interface)

- Measuring lengths: up to 16,384 mm

- High traversing speeds: up to 10 m/s

SALE

Linear encoders

- High efficiency and productivity

- Time savings – no reference run necessary on initial commissioning due to absolute position measurement

- Accurate positioning even with high mounting tolerances

- High reproducibility (0.3 mm / 1 mm), high system resolution (0.1 mm)

- SSI and PROFIBUS interfaces

SALE

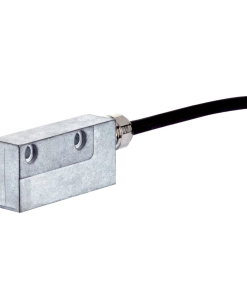

Linear encoders

- Reference traverse no longer necessary due to absolute measuring system

- Maintenance-free thanks to non-contact measuring principle

- Measured lengths of up to 1 m

- Suitable for high traverse speeds of up to 10 m/s

- HIPERFACE® interface

SALE

Linear encoders

- High travel speed linked to precise positioning increases system efficiency and improves throughput

- Camera-based system with no moving parts increases the sensor's service life, thus reducing lifecycle costs considerably

- Traversing speeds of up to 7 m/s can be achieved

- Output of position and speed data, as well as pre-failure notifications via fieldbus interfaces

- Wide operating temperature range from –30 °C to +60 °C

SALE

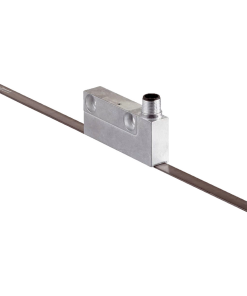

Linear encoders

- Measurement lengths of up to 4 m

- Maintenance and wear-free thanks to non-contact measurement principle

- No need for a reference run due to the absolute position recording

- For high traversing speeds of up to 10 m/s

- Reliable measurements, even in the event of contamination and condensation on the magnetic tape

SALE

Linear encoders

- 100% mechanical and electrically compatible with existing cylinder constructions.

- Save-spacing installation: Better utilization of the piston stroke in tight installation space of the cylinder

- Favorable cost-benefit ratio.

- Fluid temperature (hydraulic oil) up to max. +95 °C.

- Compact dimensions: 10 mm installation space, 30 mm cushion zone.

SALE

Linear encoders

- Low maintenance costs due to wear- and maintenance-free measurement principle.

- Absolute measurement without reference run.

- Intelligent condition monitoring enables predictive maintenance of machines.

- Resolution: up to 10 μm.

- Measuring lengths: 50 mm to 2,500 mm.