SALE

- Ability to combine multiple products to create a tailored hybrid solution.

- Read adjacent objects with "side-by-side” focusing, which increases the throughput.

- Easy installation due to the slim, sophisticated design and partial pre-assembly.

- Tracking function with MSC800.

- Integration into the network concept of the MSC800.

- JPEG image output in real time.

SALE

- Prevention of fires and traffic jams due to early detection of overheated vehicles.

- Measurement possible in flowing traffic, even at high vehicle speeds.

- 3D visualization of the vehicles.

- Can be extended, for example, to include the detection of license plates, hazardous goods plates or overheight.

- Data transmission via TCP/IP interface.

SALE

- Cost-effective retrofitting due to compatibility with existing SICK solutions.

- Shorter downtime thanks to pre-installation and commissioning by SICK.

- Identification, weighing and measurement (L/W/H) of objects.

- Modular system concept for flexible upgrading and conversion options.

- Integrated alibi memory for central storage of LFT data.

SALE

- Measuring and weighing pallets and other bulky freight items

- Available upon request: special versions for larger freight items or for dynamic measurement.

- Quick, economical commissioning thanks to pre-assembled, cabled complete system.

- Static dimensioning and weighing of pallets and other bulky freight items.

- Complete solution with folding steel tube frame, evaluation computer and touchscreen display.

SALE

Sick

- Quick and low-cost installation thanks to direct connection option for trigger sensors

- Simple connection with M12 cable for IO-Link variants

- Configuration via SOPAS ET

- Ethernet-based variants: Compatible with SICK AppSpace

- Rugged design (IP67)

SALE

- Small, slim, and sleek design enables easy integration into applications

- Slim and flat models offer flexible mounting options

- Operating range 7 m

- Response time 18 ms

- Resolution 45 mm to 25 mm

SALE

- Detection of the thinnest objects such as envelopes or metal sheets thanks to cross-beam function.

- Precise leading edge detection thanks to short response times and high resolution

- Housing dimensions: 12 mm x 24 mm, detection heights: 100 mm to 2,400 mm

- Slim and flat housing variants

- Cross-beam function: Up to 9 beams

SALE

- Maintain a high level of productivity using the anti-dither functionality

- Compatible with existing and low-cost input cards with output types like Clockwise/Counterclockwise and Signal/Direction

- Universal 4.5 V ... 30 V supply

- LEDs that indicate encoder status and output signal.

- M12 male connector, 4- or 8-pin, or universal cable outlet

SALE

Magnetic sensors

- Rugged aluminum housing

- Easy installation: Thin housing design and different measurement area variants

- IP65, IP67, IP68

- Variants with measuring ranges of 100 mm to 1,000 mm

- Integrated inertial measuring unit

SALE

Magnetic sensors

- Wide range of applications thanks to two-part structure and a particularly flat and space-saving design

- Fault-free operation thanks to large alignment tolerance and a magnet positioning aid

- Angle measuring range 0° ... 360°

- 12-bit resolution (corresponds to 0.09°)

- Up to 32 angle windows can be defined

SALE

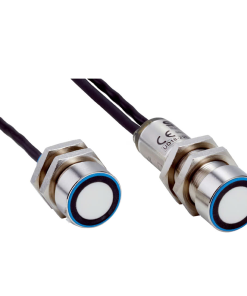

- Maximum productivity and quality thanks to reliable material transportation monitoring.

- Rapid commissioning thanks to plug-and-play plus a range of sensitivity levels to choose from.

- Variable mounting distance.

- LEDs visible from any direction.

- Immune to dirt, dust, and humidity.

SALE

- Efficient interplay in the safety system: Networking of safety sensors, safety controllers and actuators connected via Ethernet/IP™ CIP Safety™.

- Fast, intuitive commissioning: Safety Designer for the configuration of SICK system components and clever connection technology.

- Safe integration of up to 6 safety laser scanners.

- Safe integration of robot controls via Ethernet/IP™ CIP Safety™.

- Safe, integrated movement monitoring.