SALE

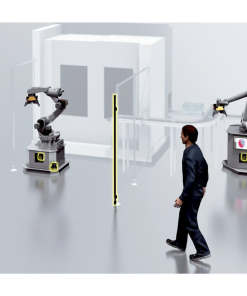

- Free, safe access to cooperative robot applications for less downtime, optimal work processes and high productivity.

- Highly flexible and future-proof solution thanks to easy tailoring of the systems to the specific robot application and production environment.

- Documentation with wiring diagram, SISTEMA file and operating instructions.

- Automated robot restart possible.

- Performance level (PL) d.

SALE

- With the certified safety system for material feeding, you save time and money: An additional safety assessment is not necessary, and elaborate mechanical protection systems are not required.

- Implement the system in tight spaces thanks to the very compact sensor housing.

- Certified up to PL d (EN ISO 13849), performance class D (IEC/TS 62998).

- High sensor availability in a miniature housing.

- Reliable object detection, remission factor: 6% to 90%.

SALE

Sick

- High level of flexibility when mounting the sensor and actuator.

- Reduced need for storage, as one sensor is suitable for a wide range of different applications.

- High level of manipulation protection due to individually coded actuator.

- PL e (EN ISO 13849), SIL3 (IEC 61508).

- Safe series connection of up to 30 sensors possible.

SALE

Sick

- Long service life due to durable and low-maintenance design.

- Just one safety switch in conjunction with a suitable safety module makes it possible to solve applications up to PL e and Cat. 4 (EN ISO 13849).

- Response range of up to 9 mm.

- 2 or 3 contacts.

- LED status indicator (RE27).

SALE

- High level of machine availability due to a rugged metal locking head and high locking force.

- High coding level of the actuator fulfills the requirements of EN ISO 14119 on manipulation protection without additional measures.

- Locking force: up to 3,900 N.

- Actuator with high coding level (EN ISO 14119).

- Enclosure rating: IP67, IP69K

SALE

- Standard device design provides quick and easy mounting.

- High availability due to rugged metal housing.

- Standardized metal housing.

- Roller plunger with stainless steel roller.

- 1 M20 x 1.5 cable entry gland.

SALE

- Standard device design provides quick and easy mounting.

- Rugged metal housing provides increased machine reliability, even when the guard has a mechanical offset.

- High availability and safety due to the cone shaped alignment aid.

- Slow-action switching elements with four contacts.

- IP 67 enclosure rating.

SALE

- Easy installation, commissioning and maintenance.

- 270° scanning angle allows allround protection using only two scanners.

- Up to 3 m protective field range.

- Up to 48 freely configurable fields and 16 switchable field sets.

SALE

- Standardized integration in FPLC controllers thanks to GSDML generic station description.

- Large protective field range of 7 m enables a large variety of applications.

- 4 m, 5.5 m or 7 m protective field range.

- 4 switchable field sets.

SALE

- Easy integration due to compact design.

- 270° scanning angle allows allround protection using only two scanners.

- Up to 3 m protective field range.

- EFI interface for safe SICK device communication.

SALE

- Intuitive configuration software featuring comprehensive functions for straightforward engineering.

- Rapid verification of the safety application: The configuration software provides documentation and a wiring diagram.

- Safe controller networking with Flexi Line.

- Safe series connection with Flexi Loop.

- Safe drive monitoring.

SALE

- Low price and maintenance-free.

- Standard-compatible transponders enable future-proof solutions.

- Mounting on various materials possible, even on metallic surfaces.

- Ambient temperature range from −40 °C to +230 °C.