SALE

- Supports the driver when reversing but does not distract him when driving forwards.

- Actively warns the driver with acoustic and visual warning signals.

- Cost-efficient solution for retrofitting on a large number of vehicles thanks to different voltages and electrical systems.

- Monitored areas scalable with a second TiM3xx LiDAR sensor.

- Control unit provides the necessary logic for the sensors and regulates its voltage supply.

SALE

- Cost-effective retrofitting due to compatibility with existing SICK solutions.

- Shorter downtime thanks to pre-installation and commissioning by SICK.

- Identification, weighing and measurement (L/W/H) of objects.

- Modular system concept for flexible upgrading and conversion options.

- Integrated alibi memory for central storage of LFT data.

SALE

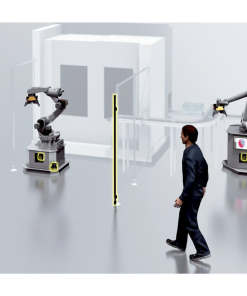

- Efficient interplay in the safety system: Networking of safety sensors, safety controllers and actuators connected via Ethernet/IP™ CIP Safety™.

- Fast, intuitive commissioning: Safety Designer for the configuration of SICK system components and clever connection technology.

- Safe integration of up to 6 safety laser scanners.

- Safe integration of robot controls via Ethernet/IP™ CIP Safety™.

- Safe, integrated movement monitoring.

SALE

- Free, safe access to cooperative robot applications for less downtime, optimal work processes and high productivity.

- Highly flexible and future-proof solution thanks to easy tailoring of the systems to the specific robot application and production environment.

- Documentation with wiring diagram, SISTEMA file and operating instructions.

- Automated robot restart possible.

- Performance level (PL) d.

SALE

- With the certified safety system for material feeding, you save time and money: An additional safety assessment is not necessary, and elaborate mechanical protection systems are not required.

- Implement the system in tight spaces thanks to the very compact sensor housing.

- Certified up to PL d (EN ISO 13849), performance class D (IEC/TS 62998).

- High sensor availability in a miniature housing.

- Reliable object detection, remission factor: 6% to 90%.

SALE

- Resistant to damage caused by mechanical and chemical stress, as well as high temperatures.

- Simple installation saves time.

- For detection of objects, surfaces, leading edges, and fluid levels.

- Threaded and smooth sleeves, bands of light (array), 90° reflection versions available.

- Plastic , protective metal or Teflon sheathing available.

SALE

- Precise, simple adjustment using a potentiometer, teach-in button or display

- The rugged VISTAL® sensor housing ensures high availability and a long service life

- Sensing range: 5 cm to 4 m

- Very small background range: 6 mm

- Switching frequencies of up to 1,000 Hz

SALE

- Simple installation

- Solutions for difficult-to-access installation sites

- High degree of economic efficiency

- Threaded and smooth sleeve heads available

- Axial and radial fiber optic head alignment available

SALE

Glare sensors

- Quick installation via alignment mode

- Integrated key lock reduces the risk of operating errors and tampering

- Sensitivity adjustments increase the system's operational safety

- IO-Link provides easy data access from the PLC

- Quick and easy configuration

SALE

- Powerful 2G fiber-optic sensor for explosive environments

- Special electronics are used to efficiently achieve long sensing distances and ranges in conjunction with fiber-optic cable systems

- Output type: EN 60947-5-6 (NAMUR)

- M12 plug or M16 screw connection: rotatable 90°

SALE

- Condition Monitoring sensors for vibration, shock, and temperature monitoring

- The Multi Physics Box Condition Monitoring sensor allows for continuous condition-based monitoring of, for example, motors, pumps, conveyor systems or fans. It measures vibrations, shocks, and temperature, thereby providing indications of potential faults and machine failures. If the measured values exceed the individually configurable thresholds, an alert is output. For vibration values, the vibration monitoring thresholds for machines according to ISO 10816-3 can be implemented via a multi-stage alert.

- The sensor can be integrated into the machine or system via IO-Link or a simple alarm-based switching signal.

- Whether on-site or in conjunction with a Cloud Service: The Multi Physics Box creates a data foundation that can be used to avoid unplanned downtime and effectively lower costs.

SALE

- The smart solution for challenging detection tasks

- With the WLL80 opto-electronic fiber optic amplifier, SICK is creating a new generation of amplifiers for the flexible integration of fiber optics in confined spaces.

- The intelligent WLL80 features IO-Link and can make processes even more efficient with various Smart Tasks. Thanks to IP54, it is protected from dust and spray water during operation. Continuous threshold adaptation ensures good performance in the long term with minimal maintenance requirements.

- In addition to a fast response time and high detection range, it is characterized by flexible and user-friendly parameterization via the OLED display or IO-Link. Whether as a single or bus version, the WLL80 is suitable for a wide range of applications thanks to its extensive fiber optics portfolio.