Powder carbon is injected into a blast furnace to support iron reduction. The combustion of CO and CO2 supplies additional energy to the melting process. The carbon is stored in silos with limited space.

When an inert silo is not used, an O2 measurement technology can be selected to detect a potential fire risk and alleviate that risk by decreasing the O2 content in the silo. Alternatively, a CO monitor can detect a fire by sensing an increase of CO. A combination of both technologies in one installation is possible and increases the overall safety level of the process.

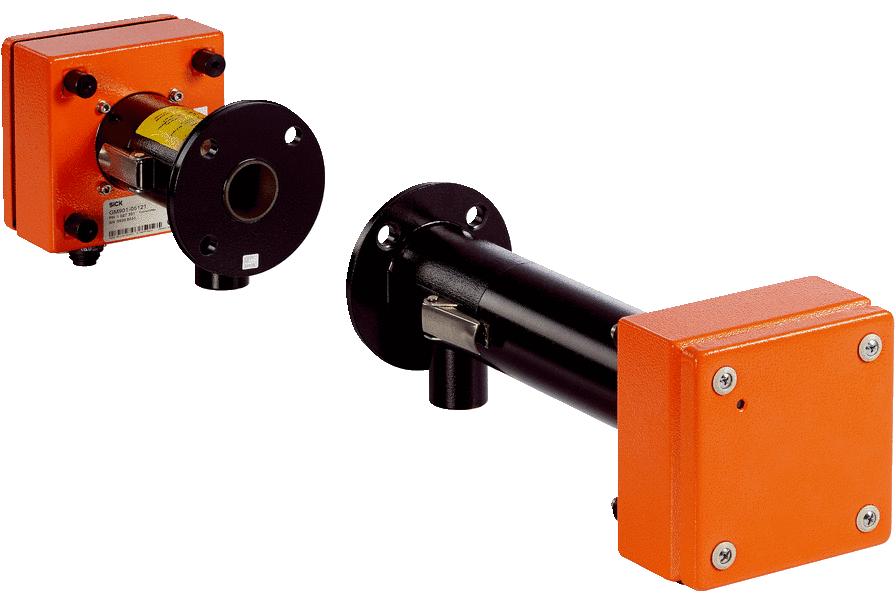

Following product families can be used

- O2transmitter based on high-performance laser spectroscopy (TDLS)

- For use in use in explosion-hazardous areas (FM, ATEX and IECEx approvals)

- Measurement directly in the process or extractive using a measurement gas cell (option)

- Designed for heavy-duty industrial applications

- Compact design and easy to operate

- Long-term stability

- No moving parts

- Representative measurement along the duct diameter

- Operation via evaluation unit

- Short response times

- Verifiable with gas-filled cell; gas-testable probe with test gas