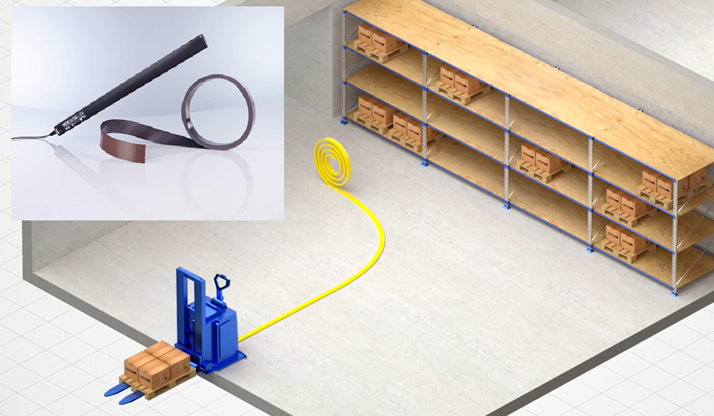

MLS – Sick Sensor, a new product that integrates many advanced features, is currently being used by many machine manufacturers and corporations in navigation for AGVs.

General introduction: AGV or Robot AGV (English: Automation Guided Vehicle) is a vehicle specifically designed to be used in the transportation of goods, finished products, materials, etc., in an automatic form.

Benefits of AGVs: AGVs are mainly used in smart factories and warehouses, thereby helping businesses improve production efficiency.

- Reduced labor costs: AGVs can transport large volumes of goods and operate independently with little human intervention.

- Improve labor productivity: AGV vehicles can operate continuously 24/7 and have high accuracy, ensuring the transportation process without errors or faults

MLS – Sick Sensor, a new product that integrates many preeminent features that are currently being used by many machine manufacturers and corporations in navigation for AGVs.

Outstanding features of MLS – Sensor SICK

- Line tracking using SICK’s magnetic line detection technology

- The ability to read 3 magnetic lines, helps AGV when entering junctions or intersections to accurately navigate the pre-programmed route.

- Built-in 10 markers (Makers) used to determine the exact position to help AGV perform different jobs such as: Turn left, right, stop to pick up or return goods … -> in small workshops, simple path, there’s no need to add an RFID kit to determine the locations

- IMU built-in inertial measurement (gyroscope-like feature) based on EULER angles calculates and keeps the vehicle balanced on uneven floors…

- Feedback the deviation of the vehicle from the magnetic tape in digital form

- The “Original Offset 0” feature and clear LED display status make installation and calibration easy.

Specifications:

- Sensor length: 200 – 600 mm

- Operating distance: 10 – 70 mm

- Resolution and repeatability: 1 mm

- Max detection: Up to 3 lanes at the same time

- Communication: CANopen, Modbus RTU RS-485