Description:

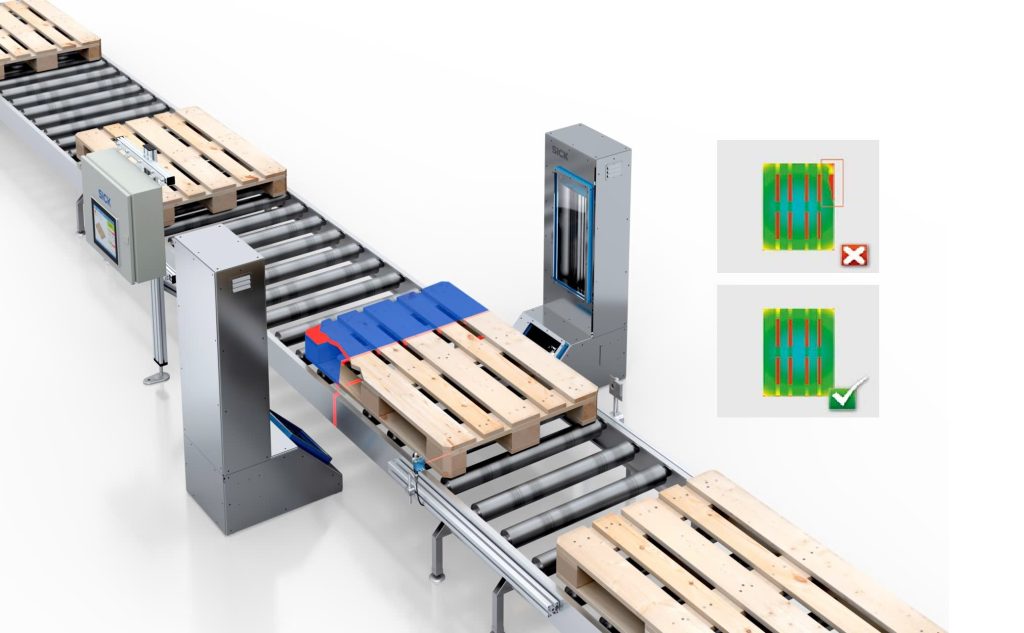

- Pallets are a fundamental component in the transportation and storage of goods. These pallets play a key role by carrying hundreds of tons of goods throughout their lifecycle. They are often subjected to rough handling and are infrequently repaired, and the potential damage to pallets can result in significant losses. This not only affects the goods but also poses risks to the health and lives of operators.

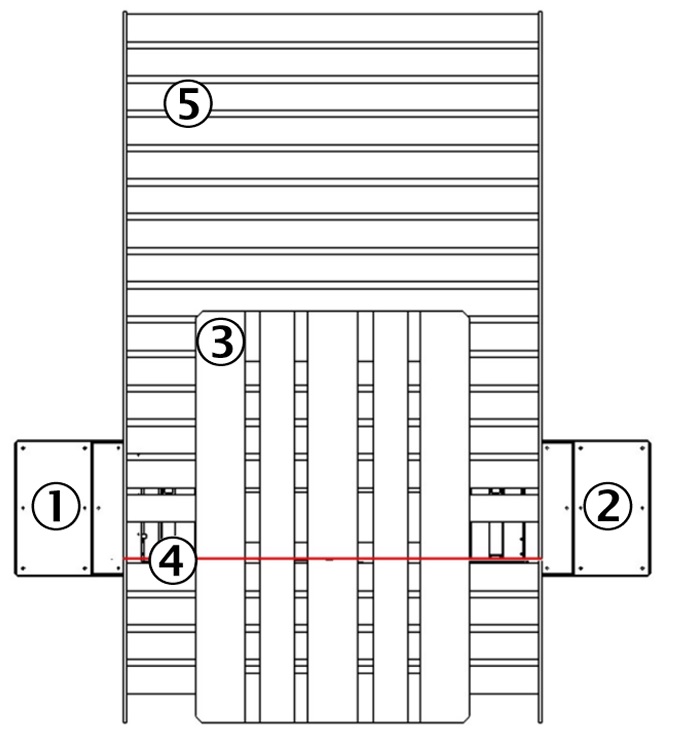

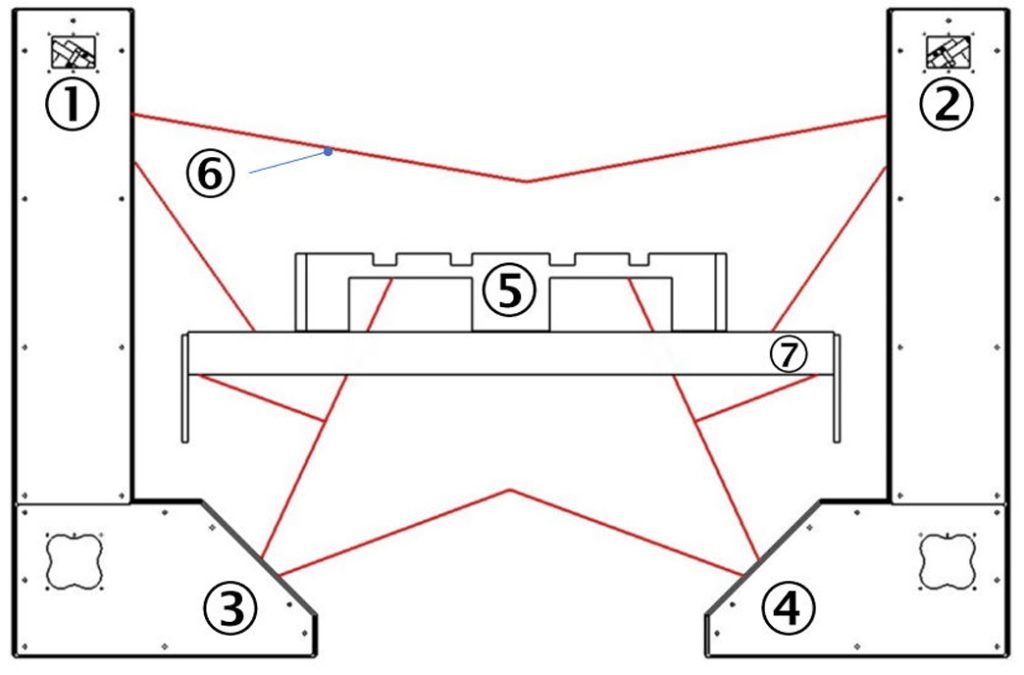

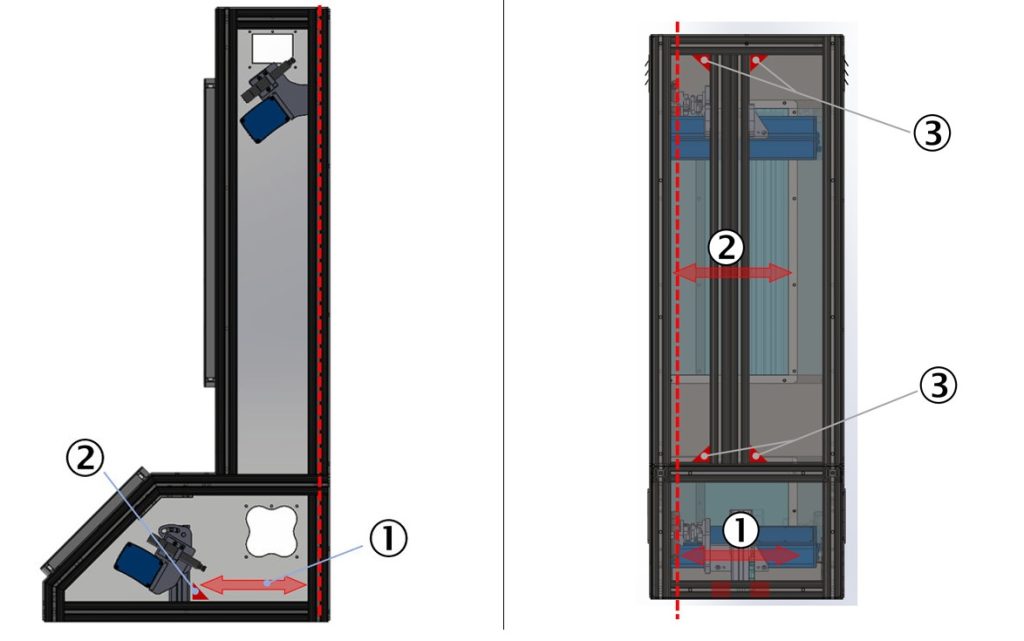

- The Pallet Integrity Inspection System (PAIS) is a non-contact quality control system based on 3D cameras that can detect damage such as missing parts, cracks and projecting nails on Euro pallets. Thanks to its modular construction, it is possible to quickly and precisely scan the top, side, bottom or inside of unloaded and loaded pallets according to requirements.

- Based on the reliable assessment of the pallet quality, the pallet can be repaired or replaced in order to avoid accidents and damage to goods. Replacing manual inspections speeds up workflows and ensures a high productivity in downstream processes.

Applications in fields:

- Depalletization lines in various industries (e.g. food and beverage).

- Monitoring of incoming and outgoing pallets in logistics processes.

- Quality control of pallets when manufacturing and repairing pallets.

Technical details:

- General camera principle: 3D laser triangulation

- 3D cameras and dual line lasers (safety class 2) enable scanning during throughput.

- Customizable limits for each defect type and individual pallet elements.

- Intuitive software operation

- Warning messages and notifications.

- Space-saving and dirt-proof system construction (optional).

Pre-alignment and camera alignment: