|

Product |

Part No. | Light spot size | Switching output |

Teach-in mode |

| KT8L-P3756 | 1041351 | Ø 3 mm | PNP | Static 2-point teach-in, Dynamic teach-in (min/max) |

| KT8L-P3656 | 1041262 | Ø 0.3 mm | PNP | Static 2-point teach-in, Dynamic teach-in (min/max) |

| KT8L-N3756 | 1041352 | Ø 3 mm | NPN | Static 2-point teach-in, Dynamic teach-in (min/max) |

| KT8L-N3656 | 1041263 | Ø 0.3 mm | NPN | Static 2-point teach-in, Dynamic teach-in (min/max) |

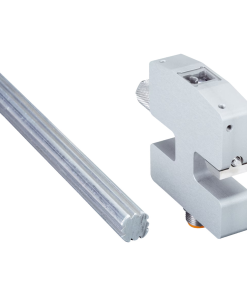

Contrast sensors KT8

- Laser contrast sensor

- Precise detection of the smallest marks and objects, e.g. 1 x 1 mm²

- Reliable operation even in the event of object jitter

- High switching sequence of 17 kHz

- Display of detection reliability via control panel

Category: Contrast sensor

Tags: KT8, laser, Sensor, Contrast sensors

At a glance:

- The KT8 sensor family features two variants. The first variant, the KT8L, enables very reliable detection of the smallest contrast marks and objects thanks to the precise laser.

- Versatile use for various distances from sensor to sensing object

- Precise detection of the smallest marks and objects, e.g. 1 x 1 mm²

- Reliable operation even in the event of object jitter

- Access to the sensor with the controller saves the machine operator time and effort during parameterization

- Individualized parameterization and setting specifically tailored to the application

- Automatic drift correction enables maximum production reliability, for example in the event of weakening print marks

- Reliable operation with high-gloss foils ensures high machine availability

Features:

- Laser variant with sensing range from 30 mm bis 800 mm

- Very small and precise laser light spot (class 2)

- High switching sequence of 17 kHz

- Display of detection reliability via control panel

- Very precise light spot

Related products

SALE

- Special housing for rapid mounting and adjustment

- Dual sensors detect double columns of marks

- Tight dual-sensor mounting ability

- Detects 1-18 marks of different colors

SALE

Switching automation light grids

- Maximum range: 2 m

- Number of beams: 26

- Minimum detectable object (MDO): ≥ 2 mm

- The quick response time of the HLG allows the customer to use higher conveyor speeds

- The highest measurement resolution for the detection of very small objects on the conveying belt enables error-free operation in edge detection applications or when counting small objects.

SALE

Image-based code readers

- Image-based code readers: 1D codes, 2D codes, Stacked, direct-marked codes

- Reading distance: 50 mm ... 300 mm

- An industrial trend: integrated optics with magnifier effect for mini codes on small components and integrated distance measurement

SALE

Fork sensors

- Functional principle: Optical detection principle

- Fork width: 3 mm

- Fork depth: 42 mm

- MDO: Gap between Labels / Size of labels: 2 mm

- Light source: LED, Infrared light

- Thanks to IO-Link or external teach-in, the switching threshold can be adapted while the process is running, increasing process reliability

- Plastic housing with IP 65 enclosure rating

- Fast response time: 50 μs

SALE

Fork sensors

- Functional principle: Optical detection principle

- Fork width: 2 mm ... 225 mm

- Fork depth: 40 mm ... 95 mm

- MDO: 0.2 mm

- Light source: LED, Infrared light/ LED, Infrared light/ LED, Infrared light

- User-friendly setting via IO-Link, teach-in button, or plus/minus buttons

- Fast response time: 100 μs