| Product | Part no. | Fork width | Fork depth | Switching output | Switching mode | Connection type | Housing material |

| WFM180-120P321 | 6037836 | 180 mm | 124 mm | PNP | Dark switching | Connector M8, 3-pin | metal |

| WFM120-120P311 | 6037833 | 120 mm | 124 mm | PNP | Light switching | Connector M8, 3-pin | metal |

| WFM80-60P321 | 6037828 | 80 mm | 60 mm | PNP | Dark switching | Connector M8, 3-pin | metal |

| WFM180-120N311 | 6037839 | 180 mm | 124 mm | NPN | Light switching | Connector M8, 3-pin | metal |

| WFM80-60P311 | 6037829 | 80 mm | 60 mm | PNP | Light switching | Connector M8, 3-pin | metal |

| WFM30-40N311 | 6037822 | 30 mm | 42 mm | NPN | Light switching | Connector M8, 3-pin | metal |

| WFM50-60N321 | 6037826 | 50 mm | 60 mm | NPN | Dark switching | Connector M8, 3-pin | metal |

| WFM80-60N321 | 6037830 | 80 mm | 60 mm | NPN | Dark switching | Connector M8, 3-pin | metal |

| WFM30-40N321 | 6037821 | 30 mm | 42 mm | NPN | Dark switching | Connector M8, 3-pin | metal |

| WFM120-120P321 | 6037832 | 120 mm | 124 mm | PNP | Dark switching | Connector M8, 3-pin | metal |

| WFM30-40P121 | 6037823 | 30 mm | 42 mm | PNP | Dark switching | Cable, 3-wire | metal |

| WFM30-40P311 | 6037820 | 30 mm | 42 mm | PNP | Light switching | Connector M8, 3-pin | metal |

| WFM120-120N311 | 6037835 | 120 mm | 124 mm | NPN | Light switching | Connector M8, 3-pin | metal |

| WFM180-120N321 | 6037838 | 180 mm | 124 mm | NPN | Dark switching | Connector M8, 3-pin | metal |

| WFM50-60N311 | 6037827 | 50 mm | 60 mm | NPN | Light switching | Connector M8, 3-pin | metal |

| WFM30-40N111S02 | 6051399 | 30 mm | 42 mm | NPN | Light switching | Cable, 3-wire | metal |

| WFM180-120P311 | 6037837 | 180 mm | 124 mm | PNP | Light switching | Connector M8, 3-pin | metal |

| WFM50-60P321 | 6037824 | 50 mm | 60 mm | PNP | Dark switching | Connector M8, 3-pin | metal |

| WFM30-40P121S01 | 6043001 | 30 mm | 42 mm | PNP | Dark switching | Cable, 3-wire | metal |

| WFM50-60P311 | 6037825 | 50 mm | 60 mm | PNP | Light switching | Connector M8, 3-pin | metal |

| WFM80-60N311 | 6037831 | 80 mm | 60 mm | NPN | Light switching | Connector M8, 3-pin | metal |

| WFM36-28P521S03 | 6070062 | 36 mm | 28 mm | PNP | Dark switching | Cable with MOLEX-connector, 4-pin | plastic |

| WFM30-40P321 | 6037819 | 30 mm | 42 mm | PNP | Dark switching | Connector M8, 3-pin | metal |

| WFM30-40P111 | 6052441 | 30 mm | 42 mm | PNP | Light switching | Cable, 3-wire | metal |

| WFM30-40N121 | 6058973 | 30 mm | 42 mm | NPN | Dark switching | Cable, 3-wire | metal |

| WFM120-120N321 | 6037834 | 120 mm | 124 mm | NPN | Dark switching | Connector M8, 3-pin | metal |

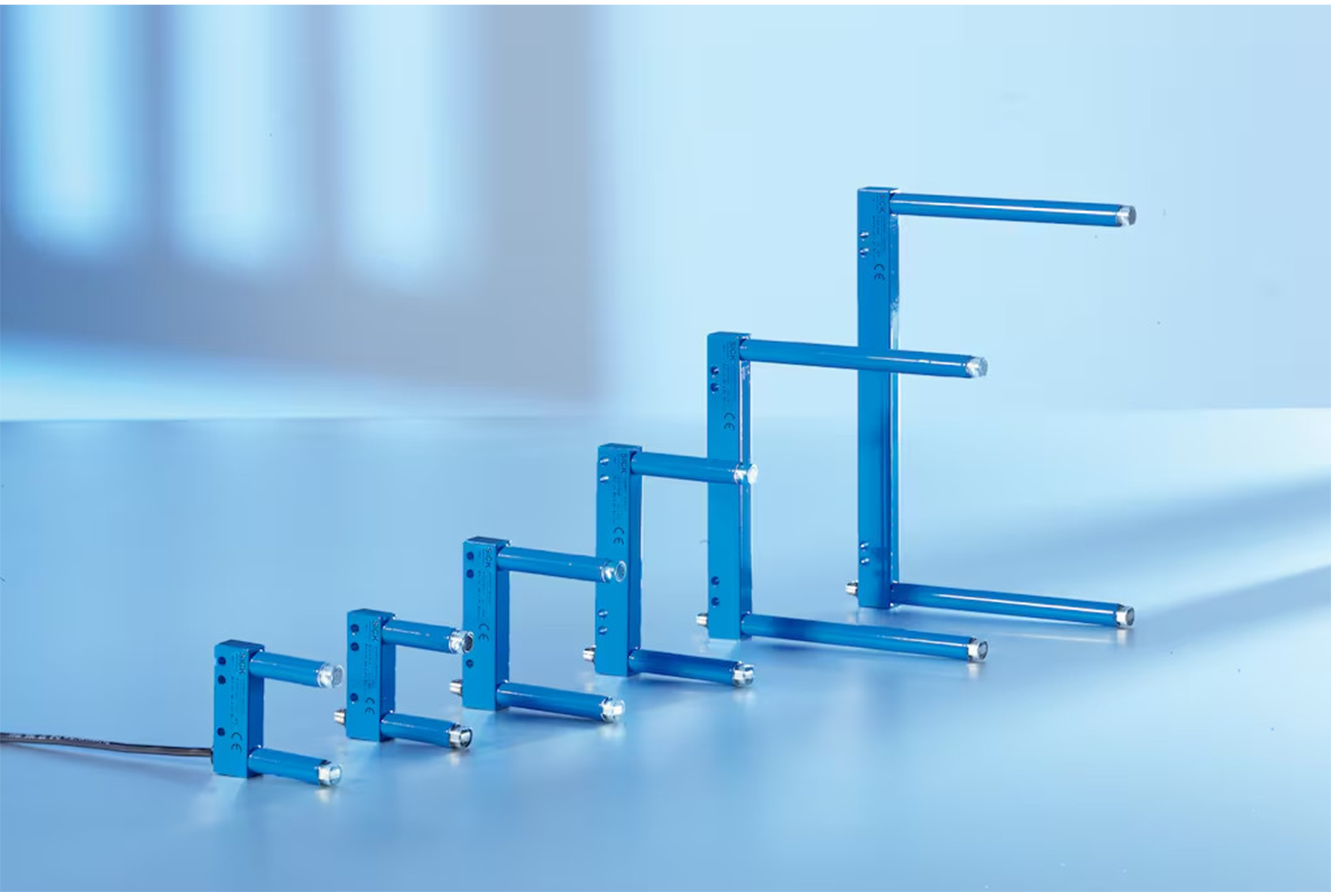

FORK sensor WFM

- Plug-and-play fork sensors – connect and get started.

- The WFM fork sensors are extremely quick and easy to mount and commission thanks to plug and play.

- Their yellow receive indicator can be seen all the way round, providing optimum feedback on the switching behavior of the WFM. Since the sender and receiver are integrated within the same housing, there is no need for any complex alignment work, allowing detection tasks to be prepared and completed quickly and easily.

- WFM have a rugged aluminum housing and are available in five different designs with fork widths ranging from 30 mm to 180 mm and fork depths of between 40 mm and 120 mm.

- SICK’s fork sensors are suited to numerous applications, such as detecting parts in production processes, checking whether various objects are present, or intralogistic processes.

Categories: Sick, Fork sensors

Tags: Sensor, Sick, FORK sensor, sensor WFM

At a glance:

- Fixed parameters guarantee a high level of operational safety with extremely simple commissioning

- A visible red light enables easy alignment of the WFM

- The all-round visible receive indicator enables constant process control

- A wide range of different fork sizes increases installation flexibility

- Stable aluminum housing for use in harsh industrial environments

Features:

- Clearly visible red emitted light

- No setup required: The sensor is ready for operation immediately

- Receive indicator, visible all-round

- 5 fork sizes with a maximum depth of 120 mm and a maximum width of 180 mm

- M12Stable aluminum housing with IP 67 enclosure rating

Related products

SALE

Sick

- Space-saving installation thanks to the slim housing

- High process accuracy because belt flutter is minimized when installed on the dispensing edge

- Detects label separations of 1 mm and greater

- Intelligent sensor with integrated IO-Link interface

SALE

- Condition Monitoring sensors for vibration, shock, and temperature monitoring

- The Multi Physics Box Condition Monitoring sensor allows for continuous condition-based monitoring of, for example, motors, pumps, conveyor systems or fans. It measures vibrations, shocks, and temperature, thereby providing indications of potential faults and machine failures. If the measured values exceed the individually configurable thresholds, an alert is output. For vibration values, the vibration monitoring thresholds for machines according to ISO 10816-3 can be implemented via a multi-stage alert.

- The sensor can be integrated into the machine or system via IO-Link or a simple alarm-based switching signal.

- Whether on-site or in conjunction with a Cloud Service: The Multi Physics Box creates a data foundation that can be used to avoid unplanned downtime and effectively lower costs.

SALE

- The CSS/CSX High Speed color sensor is characterized by its high switching frequency and its precise, infinitely variable sensitivity adjustment

- The sensor can be quickly and precisely configured for the specific application using the setup assistant in the SOPAS software.

- Up to 24 colors per identification task (job) can be saved

- IO-Link interfaces; SOPAS software with application-specific setup assistant

SALE

- Detection of magnetic lines for line guidance

- The sensor reliably differentiates between up to three lanes

- Resolution 1 mm, repeatability 1 mm

- CANopen, Modbus RTU RS-485

- Rugged aluminum housing

- Easy installation: Thin housing design and different measurement area variants

SALE

- Position sensors for T-slot

- MPS-T position sensors continuously detect the piston position of pneumatic actuators using a direct, non-contact method. They can be mounted in T-slots without the need for additional accessories.

- The sensor settings can be adjusted during installation and during operation later on, using a teach pad or – depending on the variant – using IO-Link.

- The sensors continuously supply data via analog outputs or IO-Link, enabling flexible machine concepts and making it possible to solve tasks in areas such as quality monitoring and process control in conjunction with pneumatic cylinders and drives.

- This continuous transfer of position data upgrades the functionality of the pneumatic cylinders by making them more intelligent – and, as a result, more versatile.