SALE

- Maintain a high level of productivity using the anti-dither functionality

- Compatible with existing and low-cost input cards with output types like Clockwise/Counterclockwise and Signal/Direction

- Universal 4.5 V ... 30 V supply

- LEDs that indicate encoder status and output signal.

- M12 male connector, 4- or 8-pin, or universal cable outlet

SALE

- Mounting bracket made of spring steel allows for high measurement accuracy with deflection of the measuring wheel in X and Y direction.

- Low-cost encoder with excellent quality.

- High resolution up to 0.1 mm (1 … 2,000 pulses/revolution).

- Electrical interfaces: Open Collector NPN, TTL/RS-422 or HTL/push pull.

SALE

Linear encoders

- Simple integration of the system thanks to the HIPERFACE® or HIPERFACE DSL® interface

- STL70-2 certified according to SIL2 and PL d (HIPERFACE® interface)

- Measuring lengths: up to 16,384 mm

- High traversing speeds: up to 10 m/s

SALE

- Versatile connection options for high levels of flexibility and straightforward implementation

- Compact size for compatibility with applications in which installation space is limited

- Electrical interface: 4.5 V ... 32 V; sine/cosine 1 VPP; 1,024 periods

- Enclosure rating: IP65

- Operating temperature range: –30°C ... +95°C (depending on type)

SALE

- Smart design for easy integration into the application and control environment

- Time-saving thanks to easy integration and quick commissionin

- Contact pressure can be adjusted manually from 0-24 N in 6 steps

- Compact axle spacing (120 mm) for flexible installation options

SALE

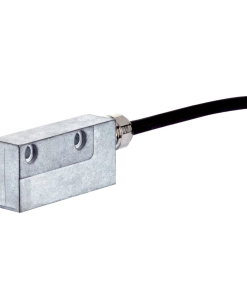

Linear encoders

- High efficiency and productivity

- Time savings – no reference run necessary on initial commissioning due to absolute position measurement

- Accurate positioning even with high mounting tolerances

- High reproducibility (0.3 mm / 1 mm), high system resolution (0.1 mm)

- SSI and PROFIBUS interfaces

SALE

Linear encoders

- Reference traverse no longer necessary due to absolute measuring system

- Maintenance-free thanks to non-contact measuring principle

- Measured lengths of up to 1 m

- Suitable for high traverse speeds of up to 10 m/s

- HIPERFACE® interface

SALE

Linear encoders

- High travel speed linked to precise positioning increases system efficiency and improves throughput

- Camera-based system with no moving parts increases the sensor's service life, thus reducing lifecycle costs considerably

- Traversing speeds of up to 7 m/s can be achieved

- Output of position and speed data, as well as pre-failure notifications via fieldbus interfaces

- Wide operating temperature range from –30 °C to +60 °C

SALE

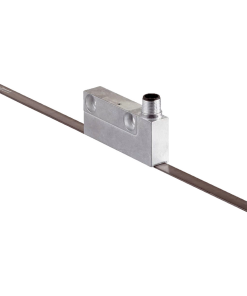

Linear encoders

- Measurement lengths of up to 4 m

- Maintenance and wear-free thanks to non-contact measurement principle

- No need for a reference run due to the absolute position recording

- For high traversing speeds of up to 10 m/s

- Reliable measurements, even in the event of contamination and condensation on the magnetic tape

SALE

Linear encoders

- 100% mechanical and electrically compatible with existing cylinder constructions.

- Save-spacing installation: Better utilization of the piston stroke in tight installation space of the cylinder

- Favorable cost-benefit ratio.

- Fluid temperature (hydraulic oil) up to max. +95 °C.

- Compact dimensions: 10 mm installation space, 30 mm cushion zone.

SALE

Linear encoders

- Low maintenance costs due to wear- and maintenance-free measurement principle.

- Absolute measurement without reference run.

- Intelligent condition monitoring enables predictive maintenance of machines.

- Resolution: up to 10 μm.

- Measuring lengths: 50 mm to 2,500 mm.

SALE

- Reduction of installation time thanks to the easy-to-mount clamping ring and the stator couplings.

- Compact, space-saving design facilitates installation in tight installation spaces.

- Pulse per revolution: Up to 8,192.

- Housing diameter: 81 mm, diameter of through hollow shaft: 30 mm or 42 mm.

- Enclosure rating: IP65