SALE

Temperature sensor

- Measuring ranges –20 °C ... +120 °C

- Pt1000 element, accuracy class A (IEC 60751)

- Accuracy of sensor element: ≤ ± (0.15 °C + 0.002 |t|)

- Very reliable: splash-proof housing, high-grade materials, rugged design, and field-proven technology

- Individually programmable transistor outputs PNP or NPN, optional analog output 4 mA ... 20 mA or 0 V ... 10 V

SALE

Temperature sensor

- Well-proven temperature measurement

- Measuring range: –50 °C +150 °C/ –50 °C +250 °C

- Accuracy of sensor element: Class A according to IEC 60751

- Accuracy of the opt. measuring transducer: ≤ ± 0.1 % of span

- Signal outputs and maximum ohmic load RA: Pt100, 4-wire, 4 mA ... 20 mA, 2-wire (RA ≤ (L+ – 10 V) / 0.028 A [Ohm])

- Electrical connection: Cable gland M16 x 1.5, IP65/ Cable gland M16 x 1.5, IP67

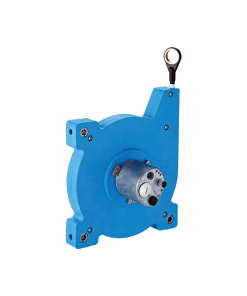

SALE

Wire encoders

- Measuring range: 0 m ... 10 m

- Resolution: 0.001 mm ... 0.14 mm

- Communication interface: IO-Link / IO-Link V1.1 / COM3 (230,4 kBaud)/ CANopen/ SSI/ PROFINET/ EtherCAT®/ EtherNet/IP™/ DeviceNet™/ PROFIBUS DP/ 4...20 mA/ 0...10 V/ Incremental / TTL / RS-422/ Incremental (HTL / Push pull)/ Incremental (TTL / HTL)

- Very small, slim housing (55 mm ... 190 mm) with spring integrated in the measurement drum

SALE

Incremental encoders

- Pulses per revolution: 0 … 1024

- Mechanical design: Solid shaft, face mount flange

- Shaft diameter: 6 mm

- Communication interfaces: TTL / RS-422, HTL / Push pull, and Open Collector

SALE

Incremental encoders

- Pulses per revolution: 0 … 2,500

- Mechanical design: Solid shaft, Servo flange/ Solid shaft, face mount flange/ Blind hollow shaft

- Shaft diameter: 6 mm feather key groove/ 6 mm/ 1/4"/ 8 mm

- Communication interfaces: TTL/RS-422, HTL/push pull, Open Collector

- Temperature range: –20 °C ... +85 °C

- Enclosure rating: IP65

SALE

Incremental encoders

- Pulses per revolution: 0 … 2,500

- Mechanical design: Solid shaft, face mount flange/ Solid shaft, face mount flange 3xM4

- Shaft diameter: 8 mm

- Communication interfaces: TTL/RS-422, HTL/push pull, Open Collector

- The high flexibility of the mechanical interface of the encoder and the available accessories allow for the use of a single design in many applications

SALE

Incremental encoders

- Pulses per revolution: 0 ... 65,536

- Sine/cosine periods per revolution: 1,024

- Mechanical design: Solid shaft, Servo flange/ Solid shaft, face mount flange/ Blind hollow shaft/ Through hollow shaft

- Shaft diameter: 6 mm/ 10 mm/ 8 mm/ 3/8"/ 12 mm/ 1/2″/ 14 mm/ 15 mm/ 5/8″

- Programmability via the PGT-08 programming software and the PGT-10-Pro display programming tool allow the encoder to be adapted flexibly and quickly according to customer needs

- Electrical interfaces: 5 V & 24 V TTL/RS-422, 24 V HTL/push pull, 5 V sin/cos 1 Vss

SALE

Adsolute encoders

- Encoder design: Multiturn / Singleturn

- Shaft type: Solid shaft, Servo flange/ Solid shaft, face mount flange/ Blind hollow shaft/ Through hollow shaft/ Shaft diameter

- High-resolution absolute encoder with up to 30 bits (AFM60) or 18 bits (AFS60)

- SSI, SSI + incremental or SSI + sin/cos interface

- Operating temperature: –40 °C ... +100 °C (depending on the type)

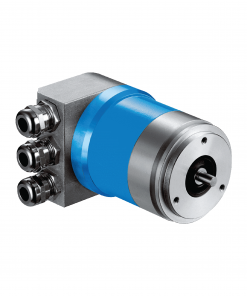

SALE

Adsolute encoders

- Encoder design: Multiturn

- Shaft type: Solid shaft, face mount flange/ Solid shaft, Servo flange/ Blind hollow shaft/ Shaft diameter

- Versatility thanks to a variety of electrical connection adapters (3x PG, 3x M12)

- Safer applications thanks to highly reliable shock and vibration resistance

- Extremely rugged, tried-and-tested absolute multiturn encoder with a resolution of up to 26 bits

- Electrical interface: PROFIBUS DP as per IEC61158 / RS 485 , electrically isolated.

SALE

Adsolute encoders

- Encoder design: Singleturn / Multiturn

- Shaft type: Solid shaft, Servo flange/ Solid shaft, face mount flange/ Blind hollow shaft/ Shaft diameter

- Easy integration into various control environments with IO-Link, CANopen and SSI interfaces

- High resistance to ambient influences due to stainless steel design and IP69K enclosure rating (Inox versions)

- 36 mm absolute encoder with maximum 26 bits (singleturn: 14 bits multiturn: 12 bits)

- IP67 to IP69K protection class

SALE

Wire encoders

- Measuring range: 0 m ... 50 m

- Resolution: 0.0008 mm ... 0.2 mm

- Communication interface: IO-Link / IO-Link V1.1 / COM3 (230,4 kBaud)/ CANopen/ SSI/ PROFINET/ EtherCAT®/ EtherNet/IP™/ PROFIBUS DP/ DeviceNet™/ 4...20 mA/ 0...10 V/ Incremental (TTL / RS-422)/ Incremental (HTL / Push pull)/ Incremental (TTL / HTL)

- Reliable solution for use in harsh ambient conditions

SALE

Wheel encoders

- Resolution in pulses/mm: 0.01 ... 12.5

- Spring deflection spring arm: ± 3 mm

- Measuring wheel circumference: Without measuring wheel / 200 mm

- Measuring wheel surface: O-ring NBR70

- Resolution: 0.08 mm per pulse, 12.5 pulses per mm

- Max. spring travel: 14 mm, mechanically limited, max. spring force: 21 N