SALE

- Easy start for anyone with the pre-installed Quality Inspection toolset of SICK Nova

- Fast, high-resolution programmable 2D cameras ensure maximum performance

- 2D vision sensors with 1.3 and 1.9 megapixels

- Flexible S- and C-mount lenses and integrated lighting

- Laser alignment aid, beeper and feedback spot

SALE

- Robust metal housing is reliable and ideal for tough environment conditions

- Visible light spot of the LUT1B version makes accurate alignment easy

- Long sensing distances up to 150 mm

- Sender LED UV (375 nm) or blue (470 nm)

- Switching frequency 600 Hz or 6 kHz

SALE

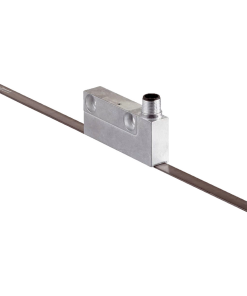

Linear encoders

- High travel speed linked to precise positioning increases system efficiency and improves throughput

- Camera-based system with no moving parts increases the sensor's service life, thus reducing lifecycle costs considerably

- Traversing speeds of up to 7 m/s can be achieved

- Output of position and speed data, as well as pre-failure notifications via fieldbus interfaces

- Wide operating temperature range from –30 °C to +60 °C

SALE

Linear encoders

- Measurement lengths of up to 4 m

- Maintenance and wear-free thanks to non-contact measurement principle

- No need for a reference run due to the absolute position recording

- For high traversing speeds of up to 10 m/s

- Reliable measurements, even in the event of contamination and condensation on the magnetic tape

SALE

2D LiDAR sensors

- Low installation costs due to large monitoring areas

- Reliable detection of small objects at long distances

- Long sensing range even when detecting dark surfaces

- High angular resolution of up to 0.0625 degrees

- High immunity to solar radiation

SALE

Sick

At a glance: Simple mounting due to lightweight design No wiring between sender and receiver Rapid diagnostics due to a 7-segment display, reducing downtime Connectivity in both back and bottom of device provide improved installation flexibility 270° scanning angle makes it ideal for both horizontal and vertical applications Features: Small, lightweight and economical measurement sensor...

SALE

- Low maintenance costs even under high mechanical loads

- Easy to install and commission

- High frequency resolution ratio

- HDDM+ and multi-echo technology

- Up to 360° aperture angle, rotatable connections and other smart features

SALE

- The very high scan rate makes the collection of large data volumes and detection of quick objects possible

- Low setup costs: Identical telegram for all 2D LiDAR sensors from SICK

- Low maintenance costs thanks to high weather resistance

- Easy configuration, with the ability to adapt to a changing environment

- Convenient and simple diagnostics via web server

SALE

- Non-contact measurement improves quality inspection during production

- High visibility LC display enables simple, cost-effective setup

- Numerous measuring ranges from 24 mm ... 26 mm to 300 mm ... 700 mm

- Maximum measurement accuracy and frequency

- Glass thickness measurement with just one sensor head

SALE

- Distance measurement using the chromatic confocal method regardless of surface and material changes

- Saves space due to the compact dimensions of the control unit and sensor heads

- Scanning frequency: up to 10 kHz

- Scanning range: 0.6 mm, 4 mm, 10 mm

- Resolving power: optionally up to 25 nm, 180 nm or 400 nm

SALE

- Quality optimization due to thickness measurement with micrometer precision

- Reliable process control of web material thanks to exact edge position determination

- Miniature metal housing

- Integrated LED alignment aid

- High-resolution CMOS receiver with high repeatability

SALE

Magnetic sensors

- Space-saving installation due to small design.

- Large operating ranges with reliable switching increase throughput.

- Electrical configuration: DC 3-wire.

- Enclosure rating: IP 67.

- Temperature range: –25 °C to +75 °C.