Description:

- Protecting vehicles, containers, and infrastructure in ports is a difficult and very challenging task. It makes high demands of drivers in particular. To assist them in their work and reduce the pressure to which they are exposed, SICK has developed an assistance system which can easily be retrofitted to reach stackers and empty container handlers. The assistant combines the company’s outstanding knowledge in the field of driver assistance systems with its reliable sensor technology.

- Maximum efficiency non-stop: container terminals, which work around the clock, 365 days a year, demand high availability and low downtimes. Increasing automation and the associated increase in container handling volumes are potentially very dangerous for reach stacker drivers.

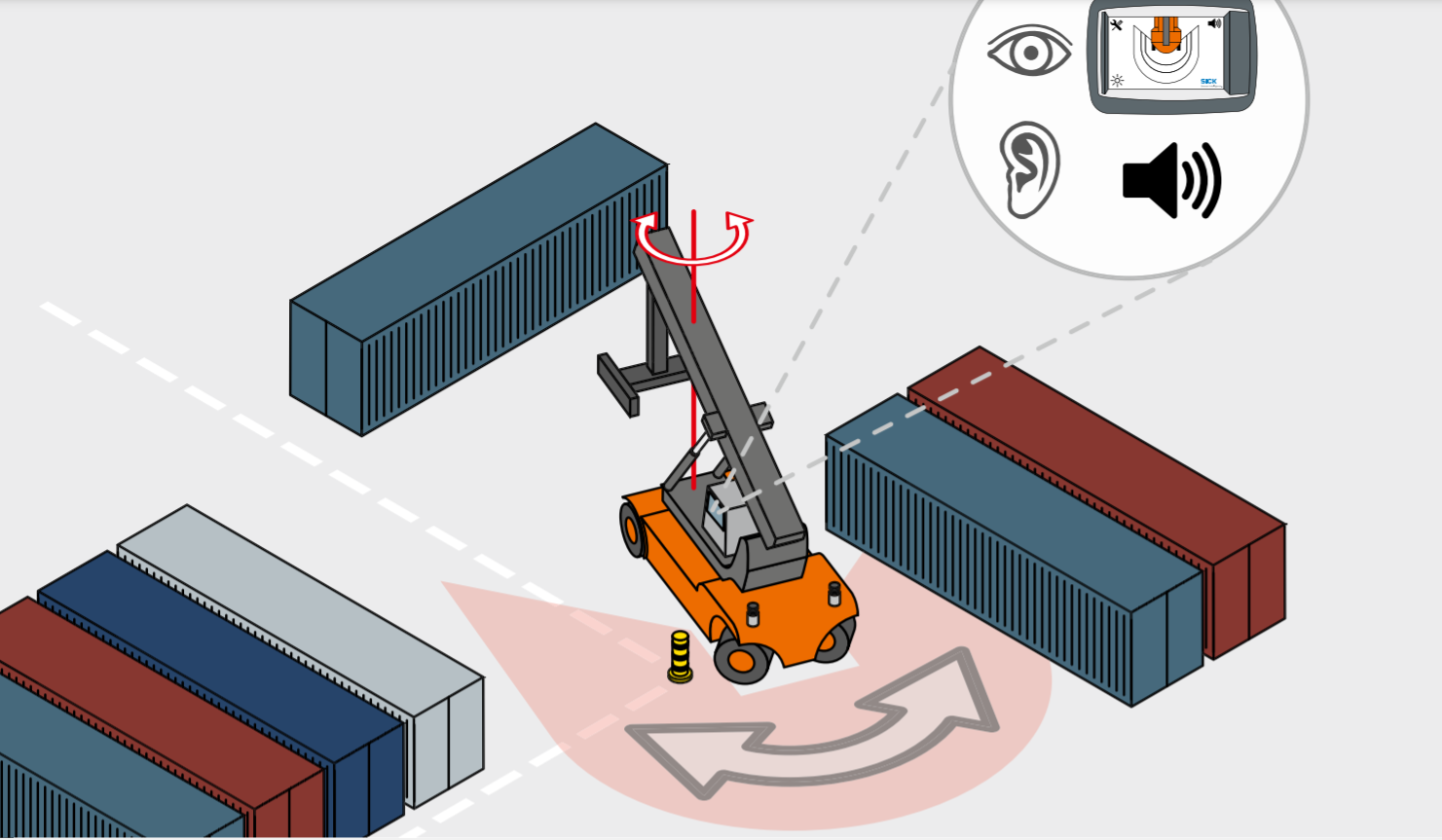

- Reach stackers and empty container handlers are large machines which transport heavy loads from A to B at high speeds. Some areas of the vehicle are not visible to the driver. The greatest danger is posed by the high dynamic response of the tail end of the vehicle, which is attributable to the rear-wheel steering and the incredibly narrow turning circle. Therefore, it is not sufficient if only the rear end of the vehicle is monitored during reversing. Accordingly, to avoid accidents, RAS Prime permanently monitors the entire rear end of the vehicle, including the sides, during reversing and forward movement.

Figure 1: System overview

At a glance:

- Conventional driver assistance systems only warn of potential collisions with other objects. SICK’s RAS Prime driver assistance system does more, permanently monitoring the area behind a reach stacker. As soon as an obstacle enters one of the three preconfigured warning zones, RAS Prime emits visual and audible signals to tell the driver that this warning zone has been violated.

- The distance warning function can be relied upon to support the driver during reversing. However, RAS Prime shows its true potential when maneuvering in narrow locations where visibility is poor.

- Due to the rear-axle steering, the tail end of a reach stacker swings out at extreme angles. Constant monitoring of the area at the rear of the vehicle gives drivers previously unachievable levels of freedom in safe maneuvering. They do not need to turn their heads, as they are kept fully informed by the display and alarms in the cab. This is even true at night, as the display features a special night mode.

- RAS Prime can be relied upon for safe driving and maneuvering at all times, day and night.

Application:

- Collision protection for reachstackers and empty container handlers for container handling in ports

Technical:

- Number of laserscanners: 2

- Supply voltage: 24 V DC, 19.2 V DC … 28.8 V DC

- Display: 4.3″ touch display

- Monitored area: Rear end, rear side left, rear side right

- Warning zones: 3

- Areas of application: Port

- Ambient temperature, operation: –25 °C … +50 °C

- Benefits: Easy installation and maintenance, Easy-to-understand display of the rear area of the vehicle, Early warning alarm to alert drivers, Permanent monitoring of the entire area at the rear of the vehicle to avoid accidents

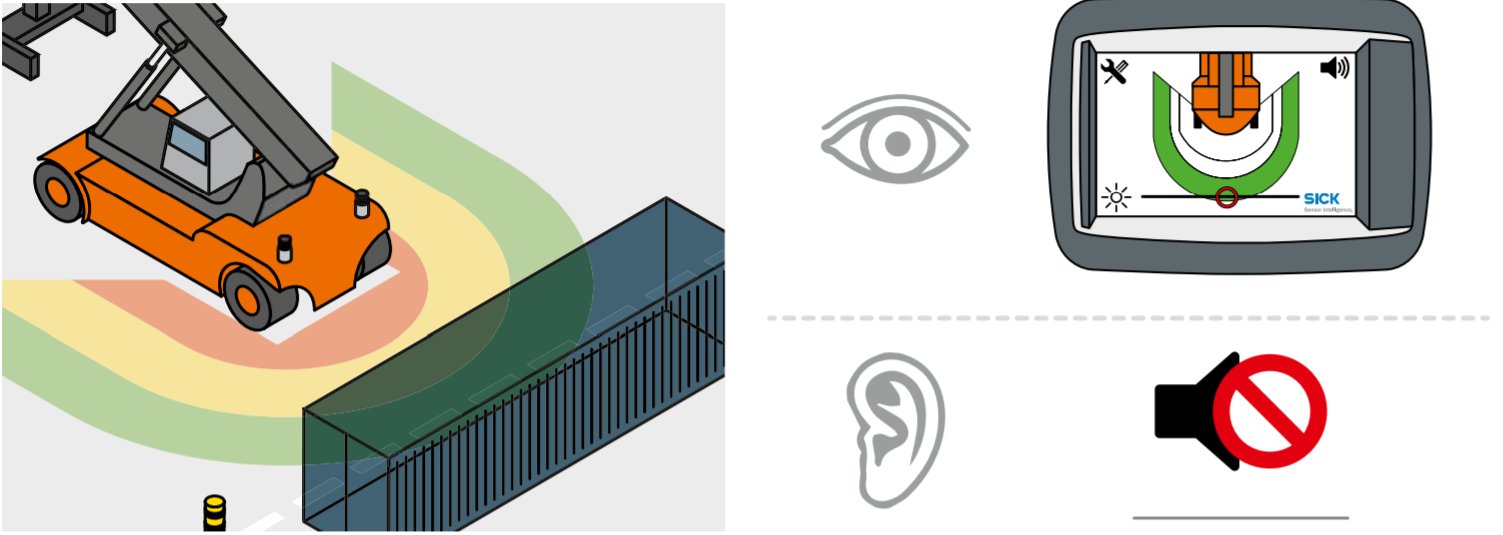

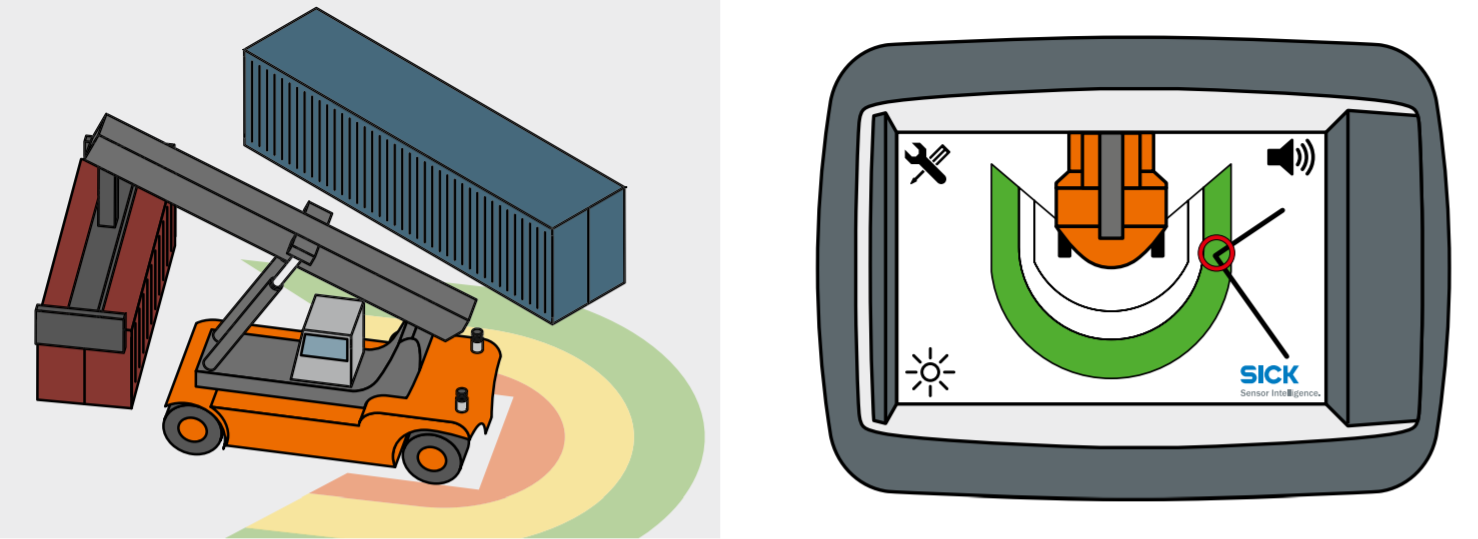

Figure 2: The first of the three warning zones is visualized in green on the display, representing the “monitoring zone”. It gives the driver an overview of the immediate vicinity. An obstacle is shown on the display as a contour but will not trigger an audible alarm.

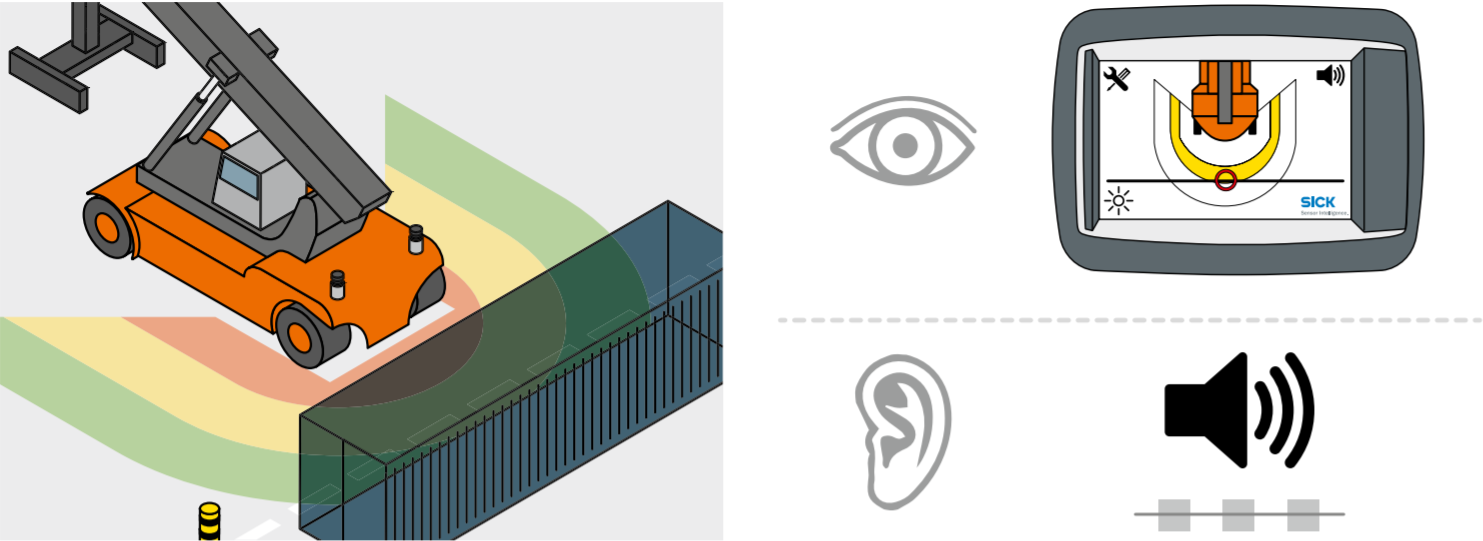

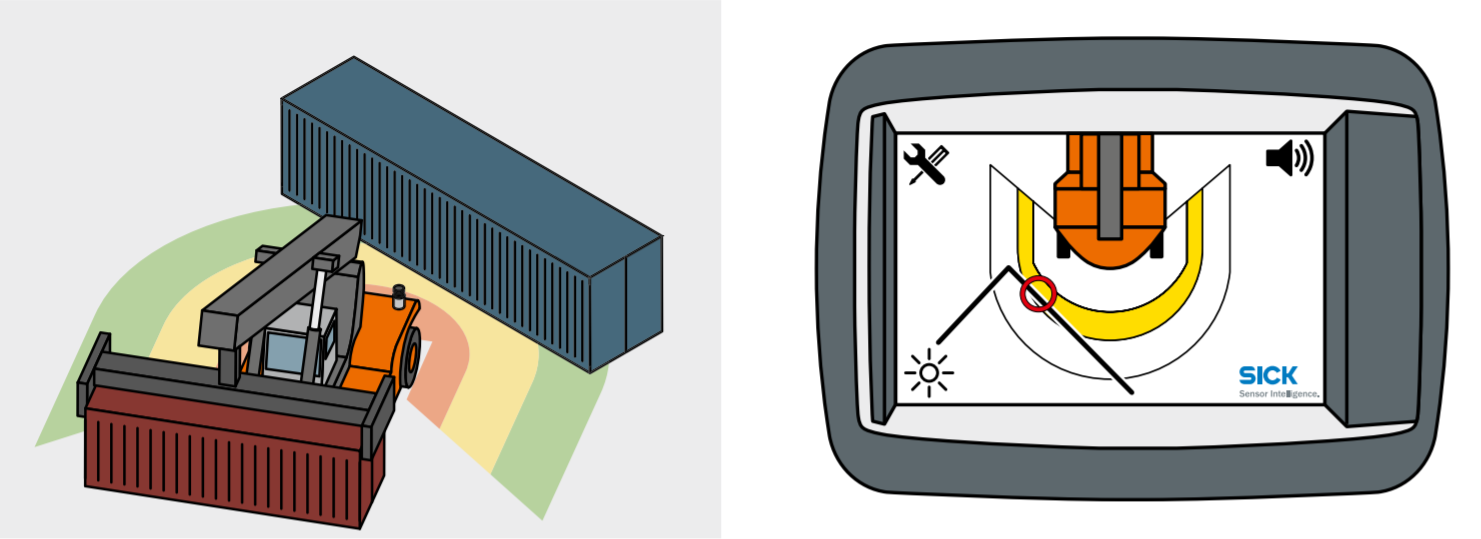

Figure 3: The zone shown in amber is the “early warning” area. As the reach stacker approaches an obstacle and enters this area, an audible signal is also triggered to increase the driver’s awareness in preparation for braking.

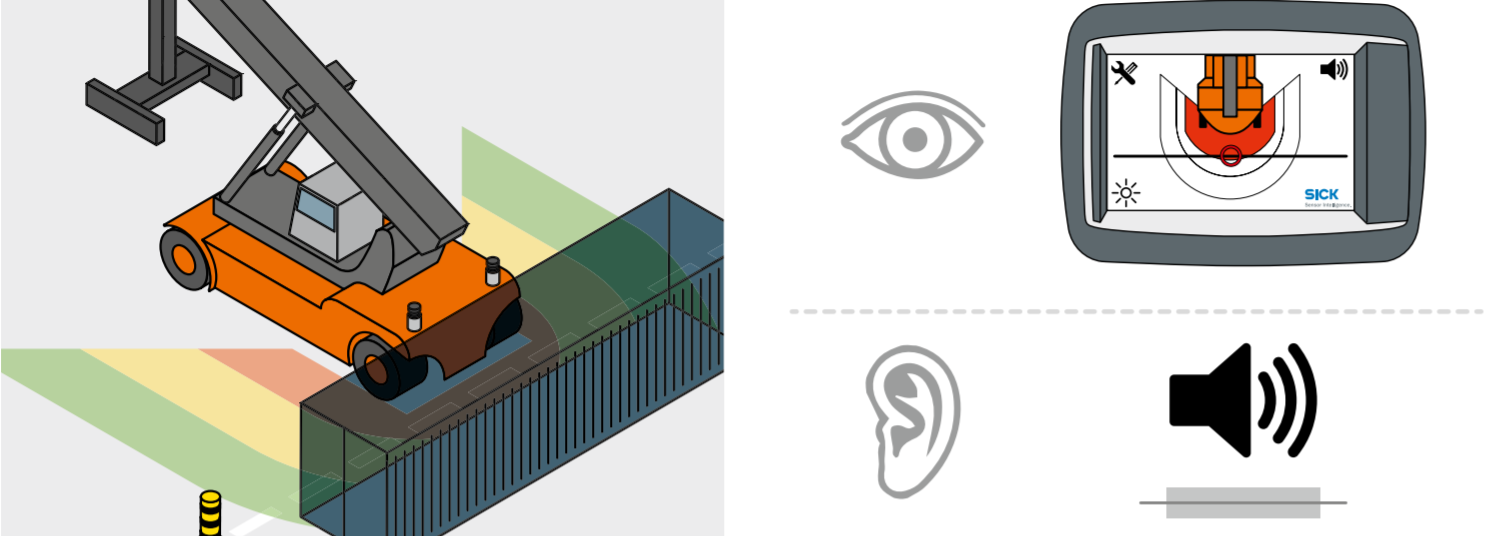

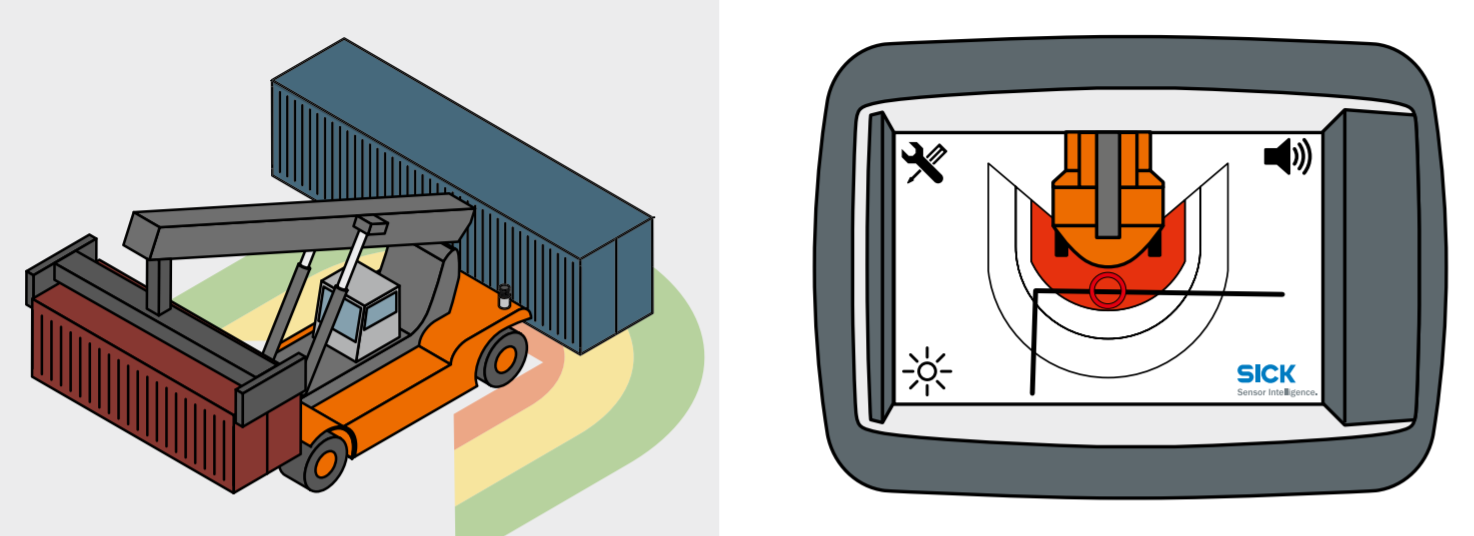

Figure 4: A “collision alarm” is triggered if an obstacle enters the zone displayed in red. Alongside the visual display, an audible signal clearly alerts the driver to the impending danger. The vehicle must be stopped immediately in order to avoid a collision.

Figure 5: RAS Prime takes the load off the driver, who needs to see the immediate vicinity from all angles during maneuvering. Objects appear on the display mirroring the surrounding environment. Whenever space is at a premium and visibility is poor, this helps drivers to estimate the distance between objects in the vicinity and the reach stacker so that they can maneuver their vehicles safely.

Figure 6: Rotation through the front axle causes the tail end to swing out sharply and an obstacle rapidly moves into the critical area of the reach stacker. The collision alarm warns the driver both visually and audibly and can prevent a collision.

Figure 7: A reassuring feeling when an acute collision hazard is averted. Even after this, with RAS Prime, the driver is able to keep an eye on the obstacles thanks to continuous monitoring – and a cool head thanks to the early warning function.

Figure 9: RAS system installed outdoors

Figure 10: RAS system SICK