Environmental regulations stipulate that certain pollutants in the exhaust gas of waste incineration plants, as well as the reference values, must be continuously monitored.

The MCS100FT can continuously measure the following components using one single extractive heated gas sample: HCl, CO, NOx as the sum of NO and NO2, SO2, NH3, O2, H2O, CO2, Cges, and HF. For normalization, the pressure and temperature parameters are also recorded. The QAL3 thorough check can be carried out without test gas with the certified, integrated calibration filter.

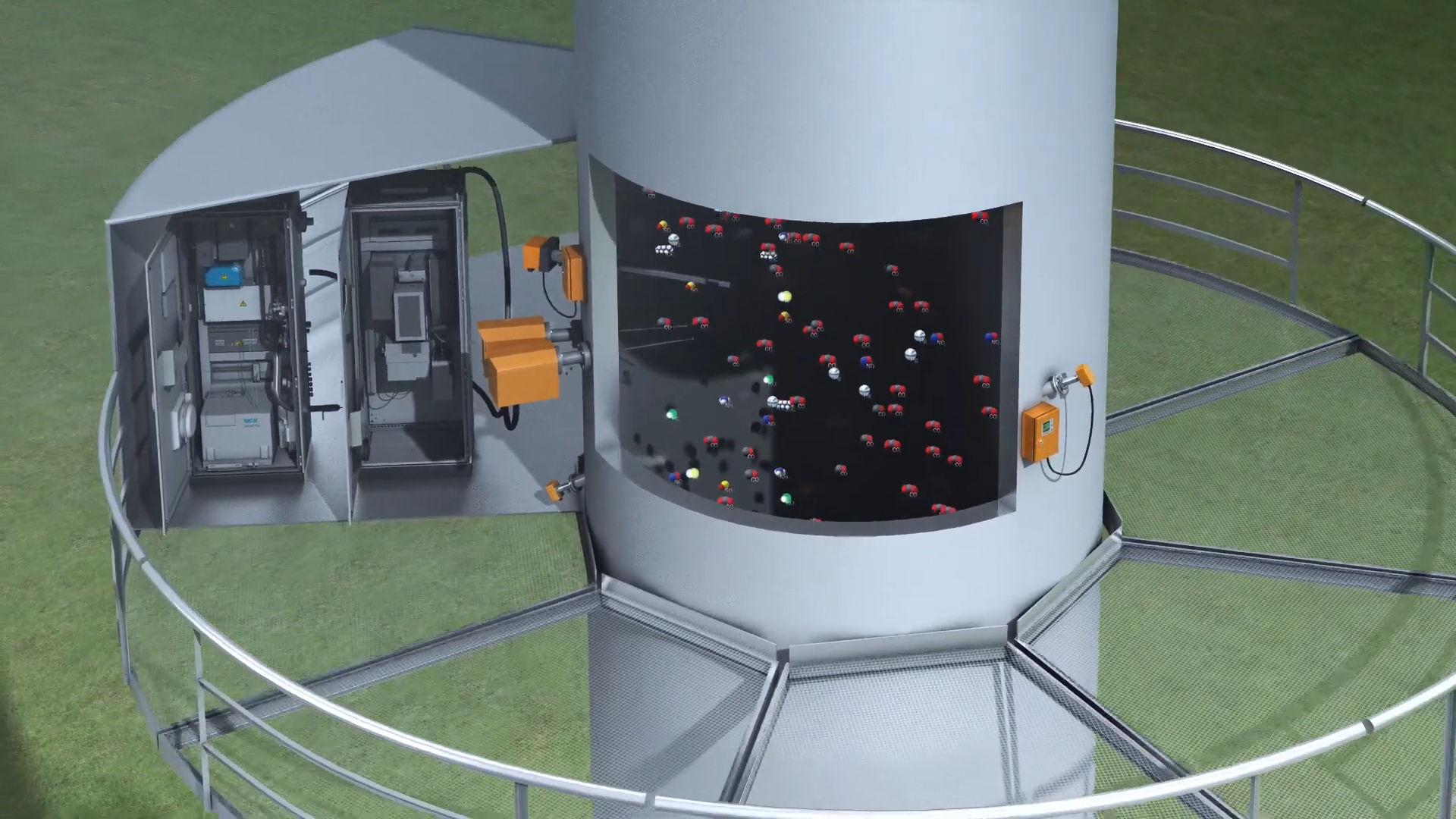

If automated HF measurement system is required for emission measurement, the MCS200HW multi-component emission measurement system can optionally also be used.

The MERCEM300Z with Zeeman measurement technology and its own gas sampler can be used for continuous mercury emission measurement. The smallest certified measuring range of this system in accordance with EN-15267 is 0 – 10 µg/m³, which therefore makes it suitable not only for continuous monitoring of the annual threshold of 10 µg/m³ that applies in Germany, but also for the upcoming new thresholds of the BAT-AELs under the WI BREF.

Following product families can be used:

|

|

MCS200HW

|

|

|

MCS100FT

|

|

|

MERCEM300Z

|