SALE

- Supports the driver when reversing but does not distract him when driving forwards.

- Actively warns the driver with acoustic and visual warning signals.

- Cost-efficient solution for retrofitting on a large number of vehicles thanks to different voltages and electrical systems.

- Monitored areas scalable with a second TiM3xx LiDAR sensor.

- Control unit provides the necessary logic for the sensors and regulates its voltage supply.

SALE

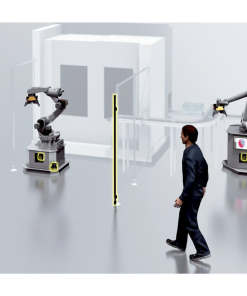

- Efficient interplay in the safety system: Networking of safety sensors, safety controllers and actuators connected via Ethernet/IP™ CIP Safety™.

- Fast, intuitive commissioning: Safety Designer for the configuration of SICK system components and clever connection technology.

- Safe integration of up to 6 safety laser scanners.

- Safe integration of robot controls via Ethernet/IP™ CIP Safety™.

- Safe, integrated movement monitoring.

SALE

- Free, safe access to cooperative robot applications for less downtime, optimal work processes and high productivity.

- Highly flexible and future-proof solution thanks to easy tailoring of the systems to the specific robot application and production environment.

- Documentation with wiring diagram, SISTEMA file and operating instructions.

- Automated robot restart possible.

- Performance level (PL) d.

SALE

- With the certified safety system for material feeding, you save time and money: An additional safety assessment is not necessary, and elaborate mechanical protection systems are not required.

- Implement the system in tight spaces thanks to the very compact sensor housing.

- Certified up to PL d (EN ISO 13849), performance class D (IEC/TS 62998).

- High sensor availability in a miniature housing.

- Reliable object detection, remission factor: 6% to 90%.

SALE

- Safety level: Type 4, PL e, SIL3, SILCL3

- Scanning range: 20 m / 70 m

- Rugged, ensures reliability under extreme ambient conditions

- Well-suited to extreme ambient conditions such as heat, cold or moisture

- Few variants because of a uniform sender

- Easy electrical integration using cable gland and relay outputs

SALE

- Scanning range: 5 m / 10 m / 60 m

- Type 2 (IEC 61496), SIL1 (IEC 61508), PL c (EN ISO 13849), only in conjunction suitable testing device, e.g., Flexi Classic or Flexi Soft

- Flexible device integration makes it possible to set up individual access protections

- Well suited to withstand extreme ambient conditions such as heat, cold or moisture