SALE

Sales Promotion

- Cylinder type: Round body

- Cylinder types with adapter: Profile cylinder /Tie rod cylinder/ Round body cylinder /Dovetail groove cylinder /SMC rail CDQ2 /SMC rail ECDQ2

- Power supply: 10 V DC ... 30 V DC

- Output function: NPN/NO

- Connection type: Cable, 3-wire, 2 m

- Enclosure rating: IP67

SALE

Sales Promotion

- Head A: female connector, M12, 5-pin, straight, shielded, for cable diameter 4.5 mm ... 7 mm

- Head B: -

- Locking nut material: CuZn, nickel-plated brass

- Shielding: Shielded

- Reference voltage: ≤ 30 V AC, ≤ 36 V DC

- Signal type: CANopen, DeviceNet™

- Enclosure rating: IP67

SALE

Sales Promotion

- Signal connection for distance sensor DME5000

- Connection type head A: Female connector, M16, 8-pin, straight

- Connection type head B: Flying leads

- Cable: 5 m, PUR, halogen-free

- Jacket material: PUR, halogen-free

- Shielding: Shielded

SALE

Sales Promotion

- Accessory group: Terminal and alignment brackets

- Material: Stainless steel

- Description: Alignment unit for DME5000, stainless steel (1.4541), incl. mounting material, additional base plate mounting kit required

SALE

Sales Promotion

- Accessory group: Terminal and alignment brackets

- Material: Steel, zinc coated

- Description: Alignment unit for DMT/DML, incl. mounting material

SALE

Sales Promotion

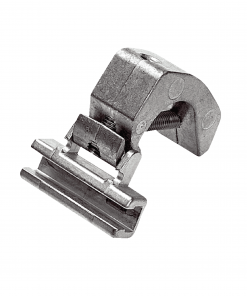

- Accessory group: Brackets for cylinder sensors

- Material: Zinc diecast

- Description: Mounting bracket for integrated profile cylinder/tie-rod cylinder

SALE

Sales Promotion

- Accessory group: Mounting brackets and plates

- Material: Stainless steel

- Description: Mounting bracket, large

SALE

Sales Promotion

- Accessory group: Universal bar clamp systems

- Material: Steel, zinc coated

- Description: Plate C for universal clamp bracke

SALE

Sales Promotion

- Accessory group: Mounting brackets and plates

- Material: Steel, zinc coated

- Description: Mounting bracket for M18 sensors

SALE

Miniature

- Sensing range max: 0 mm ... 1,000 mm

- Minimum detectable object: 0.1mm

- The ultra-thin G2 Flat sensors can be integrated into miniature plants and very tight installation spaces

- BGS: Object detection starting from just 8 mm

SALE

Miniature

- Sensing range max: 0.02 m ... 3 m

- Light source: PinPoint LED

- Adjustable BGS photoelectric proximity sensor with an sensing range up to 120 mm

- Reliable detection of jet-black, poorly reflective and highly reflective objects

- PinPoint LED ensures high sensing ranges and reliable object detection

SALE

Miniature

- Sensing range max: 0 m ... 0.5 m

- Light source: LED

- One of the smallest photoelectric sensors in the world

- No external amplifier required

- Variant designed to detect transparent and glossy objects