Markem-Imaje is a trusted global manufacturer of product identification and traceability solutions. Markem’s connected solutions help manufacturers reduce waste, increase efficiency, achieve compliance and protect their brands.

I. Introduction of MARKEM inkjet printer application – IMAJE

I. Introduction of MARKEM inkjet printer application – IMAJE

Markem-Imaje is a trusted global manufacturer of product identification and traceability solutions. Our connected solutions help manufacturers reduce waste, increase efficiency, achieve compliance and protect their brands.

In addition, Markem-Imaje inkjet printer models meet all harsh production environments with IP55 standard, Colos software system that connects customers’ production systems into a single system. Markem-Imaje inkjet printer can be applied in many manufacturing industries such as food, plastic pipes, iron and steel, corrugated iron, medical …

II. Structure principle of inkjet printer MARKEM – IMAJE

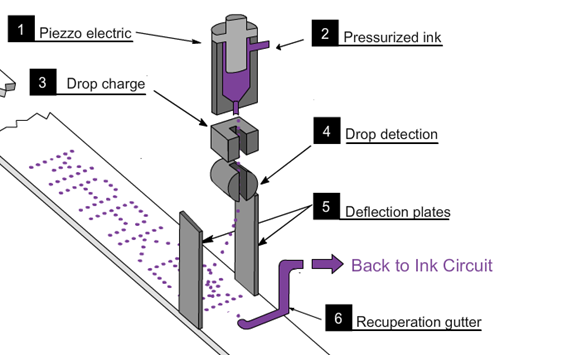

Working principles:

The ink that is pumped into the ink tank is compressed with high pressure, then passes through the ink flow divider valve (dot), then the ink droplets will be charged and released down the path of the nozzle.

The ink flow in the inkjet printer will move continuously even when not printing, the uncharged ink drops will return to the ink tank.

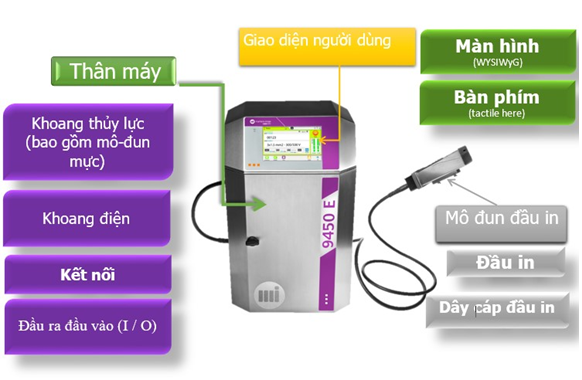

The main structure of the markem – imaje machine: The machine is composed of two main parts, the body and the print head.

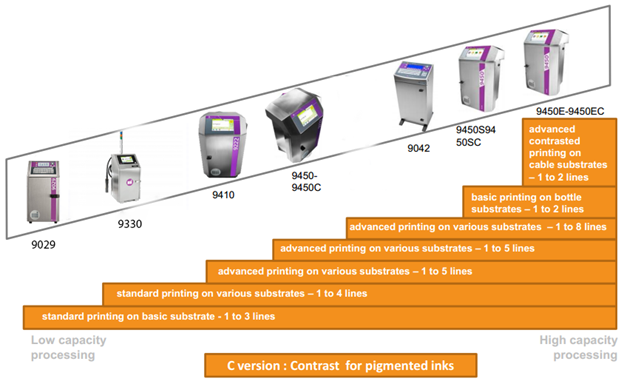

Markem – Imaje also has a variety of product lines from basic to advance:

- CIJ 9029 series: designed with outstanding advantages to reduce solvent consumption by 15% compared to the old model.

- CIJ 9330 series: designed for low to medium power applications, the 7-inch touch screen is easy to operate.

- CIJ 9410 series: designed with stainless steel shell, touch screen combined with a closed ink and solvent system to save materials by 20%.

- The CIJ 9450 series: the most advanced machine manufactured to improve production efficiency, maximize error messages in continuous operation, and the outstanding speed 9450 series is designed to perform the above requirements.

- CIJ 9450E series: inkjet printers made for cables and wires. The machine is designed to print up to 3000km of products without having to clean the printhead, and the print speed is also increased by 20%, the maximum speed is 1000m/p, which can completely meet the production lines.

- CIJ 9450C series: inkjet printer series manufactured for special customer requirements. The machine can print color inks such as red, white, and yellow to print on materials that require color contrast so that customers can clearly see the product’s parameters.