MCS200HW system

- Measured values: CH4, CO, CO2, Corg, HCl, H2O, H2SO4, NH3, NO, NO2, N2O, O2, SO2, SO3

- Performance-tested measurands: CH4, CO, CO2, Corg, HCl, H2O, NH3, NO, NO2, N2O, O2, SO2

- Measurement principles: Interference filter correlation, Gas filter correlation

- Measuring distance: 8.48 m

- Gas flow rate: 200 l/h … 400 l/h

- Measuring ranges:

CH4: 0 … 70 ppm / 0 … 700 ppm

CO: 0 … 60 ppm / 0 … 8,000 ppm

CO2: 0 … 25 Vol.-% / 0 … 50 Vol.-%

Corg: 0 … 15 mg/m³ / 0 … 10,000 mg/m³

HCl: 0 … 9 ppm / 0 … 1,840 ppm

H2O: 0 … 40 Vol.-%

H2SO4: 0 … 50 ppm / 0 … 200 ppm

NH3: 0 … 15 ppm / 0 … 650 ppm

NO: 0 … 110 ppm / 0 … 1,865 ppm

NO2: 0 … 25 ppm / 0 … 240 ppm

N2O: 0 … 50 ppm / 0 … 1,015 ppm

O2: 0 … 25 Vol.-%

SO2: 0 … 26 ppm / 0 … 875 ppm

SO3: 0 … 50 ppm / 0 … 200 ppm

- Certified measuring ranges:

CH4: 0 … 50 mg/m³ / 0 … 500 mg/m³

CO: 0 … 75 mg/m³ / 0 … 10,000 mg/m³

CO2: 0 … 25 Vol.-%

Corg: 0 … 15 mg/m³ / 0 … 50 mg/m³ / 0 … 150 mg/m³ / 0 … 500 mg/m³

HCl: 0 … 15 mg/m³ / 0 … 3,000 mg/m³

H2O: 0 … 40 Vol.-%

NH3: 0 … 10 mg/m³ / 0 … 500 mg/m³

NO: 0 … 150 mg/m³ / 0 … 2,500 mg/m³

NO2: 0 … 50 mg/m³ / 0 … 500 mg/m³

N2O: 0 … 100 mg/m³ / 0 … 2,000 mg/m³

O2: 0 … 25 Vol.-%

SO2: 0 … 75 mg/m³ / 0 … 2,500 mg/m³

- Response time (t90): ≤ 200 s

- Accuracy: ≤ 2 %, Relative to measuring range end value

- Sensitivity drift : ≤ 3 % within the maintenance interval, relative to measuring range full scale

- Zero point drift: < 3 % of the measuring range full scale value per maintenance interval

- Reference point drift:< 3 %: of the measuring range full scale value per maintenance interval

- Detection limit:

≤ 2 %: relative to measuring range end value

TOC measurement: 0.05 mg/m³

- Reproducibility :

≤ 3.3 %: relative to measuring range end value

O2 measurement: ≤ 0.2 Vol.-%

- Uncertainty of measurement: ≤ 2 %, Of measuring range full scale

- Process temperature: ≤ +1,300 °C

- Sample gas temperature: Inlet analyzer system ≤ +200 °C

- Process pressure: 850 hPa … 1,100 hPa

- Process gas humidity: ≤ 40 Vol.-%

- Ambient temperature: +5 °C … +40 °C

- Storage temperature: –20 °C … +70 °C

- Ambient pressure: 850 hPa … 1,100 hPa

- Ambient humidity: ≤ 90 %, Relative humidity; non-condensing

- Conformities: Approved for plants requiring approval

2000/76/EC (17. BImSchV)

2001/80/EC (13. BImSchV)

27. BImSchV

EN 15267

EN 14181

- Electrical safety: CE

- Enclosure rating: IP54

- Analog outputs: 0/4 … 22 mA, 500 Ω, Number depends on system configuration

- Analog inputs: 0/4 … 22 mA, 100 Ω, Number depends on system configuration; electrically isolated

- Digital outputs : 48 V AC, 0.5 A, 35 W / 48 V DC, 0.5 A, 24 W, Number depends on system configuration; electrically isolated

- Digital inputs: 3.9 V, 4.5 mA, 0.55 W, Number depends on system configuration

- Communication interface: Modbus/ PROFIBUS DP/ Ethernet

- Type of fieldbus integration: TCP/ RTU RS-485

- Function: Connection to SOPAS ET software or OPC server

- Number: 1

- Indication: LC display

- Status LEDs: “Power,” “Failure,” and “Maintenance request”

- Input: Touchscreen

- Operation: Via LC display or SOPAS ET software, multiple operating levels, password-protected

- Menu languages: German, English

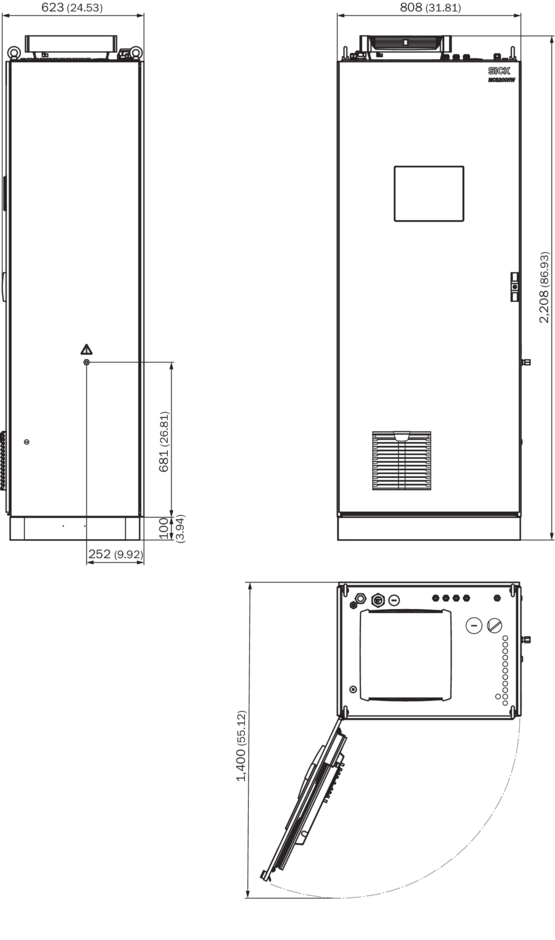

- Dimensions (W x H x D): 808 mm x 2,208 mm x 623 mm (for details see dimensional drawings)

- Weight: Approx. 250 kg

- Material in contact with media: Stainless steel 1.4571, PTFE, aluminium, coated

- Power supply:

Voltage: 115 V / 230 V

Frequency: 50 Hz / 60 Hz

Power consumption: Analyzer: ± 1,000 W/ Sample gas line, heated: ± 95 W/m/ Gas sampling unit: ± 450 W/ Heated probe tube: ± 450 W

- Auxiliaries:

Instrument air (zero gas quality): ≤ 350 l/h, 6 … 7 bar; particle size max. 1 µm; oil content max. 0.1 mg/m³; pressure condensation point max. –40 °C, purity class 2 (ISO 8573)

Instrument air (propellant air for ejector): ≤ 1,300 l/h, 5 … 7 bar; particle size max. 5 µm; oil content max. 1 mg/m³; pressure condensation point max. -+3 °C, purity class 3 (ISO 8573)

Reference gas: ≤ 350 l/h, Max. 4 bar; the reference gas must comply with the requirements of the applicable standards and guidelines

- Sample gas connections:

Sample gas inlet: Clamping ring fitting for 6 mm pipes

- Auxiliary gas connections:

Propellant air for ejector: DN 6/8

Reference gas Clamping ring fitting for 6 mm pipes

Exhaust gas outlet: DN 8/10

- Corrective functions: Drift correction and optical monitoring function via adjustment cell

- Test functions: Automatic check cycle for zero and span point

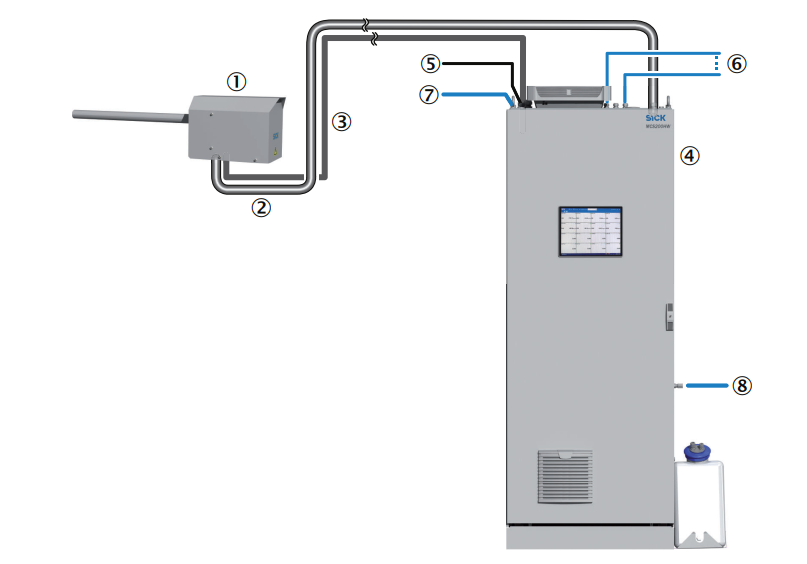

- System components:

Gas sampling unit

Sample gas line

Analyzer cabinet

- Options: GMS811 FIDORI