GM32 system; standard and Ex-version

- Description: In-situ gas analyzer for emission monitoring and process measurement

- Measured values: NO, NO2, NH3, SO2

- Performance-tested measurands: NO, SO2

- Measurement principles: Differential optical absorption spectroscopy (DOAS)

- Measuring ranges:

NH3: 0 … 30 ppm / 0 … 2,600 ppm

NO: 0 … 40 ppm / 0 … 1,900 ppm

NO2: 0 … 50 ppm / 0 … 1,000 ppm

LowNO2: 0 … 20 ppm / 0 … 1,000 ppm

SO2: 0 … 32 ppm / 0 … 7,000 ppm

- Measuring ranges refer to 1 m measuring path

- Measuring ranges depend on application and device version

- Certified measuring ranges:

NO: 0 … 70 mg/m³ / 0 … 700 mg/m³ / 0 … 1,302 mg/m³

SO2: 0 … 75 mg/m³ / 0 … 1,000 mg/m³ / 0 … 2,500 mg/m³

With an active measuring path length of 1.86 m (cross- duct), 1.25 m (open path measuring probe) or 1 m (open path measuring probe, LowNO2)

The gas-testable measuring probe (GPP) is not TUV approved

- Response time (t90):

Open measuring probe (GMP): ≥ 5 s

Gas-testable measuring probe (GPP): ≥ 120 s

Cross-duct version: ≥ 5 s

Response time adjustable

- Accuracy:

NH3:± 2 %

NO: ± 2 %

NO2: ± 2 %

SO2: ± 2 %

Relative to the smallest measuring range

- Ambient temperature: –20 °C … +55 °C

Temperature change maximum: ±10 °C/h

- Storage temperature: –20 °C … +55 °C

Temperature change maximum: ±10 °C/h

- Ambient humidity: ≤ 95 %, Relative humidity; non-condensing

- Conformities:

Approved for plants requiring approval

2001/80/EC (13. BImSchV)

2000/76/EC (17. BImSchV)

27. BImSchV

TA-Luft (Prevention of Air Pollution)

EN 15267

EN 14181

MCERTS

GOST

Ex-approvals

IECEx Ex pzc op is [ia] IIC T3 Gc

ATEX II 3G Ex pzc op is [ia] IIC T3 Gc

- Electrical safety: CE

- Mounting:

Mounting flange, DN125, PN6

Mounting flange, ANSI, 5″

- Test functions:

Internal zero point check

Check cycle for zero and span point according to QAL3

- Options:

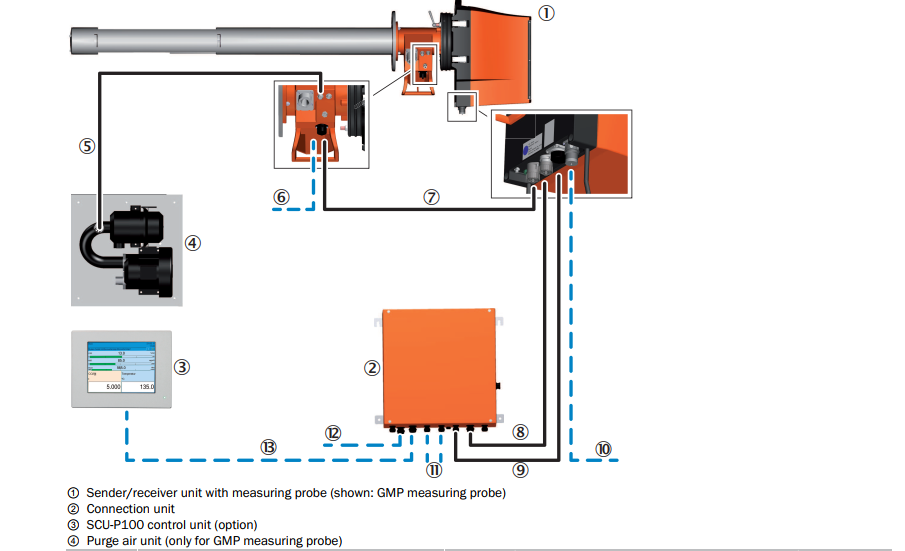

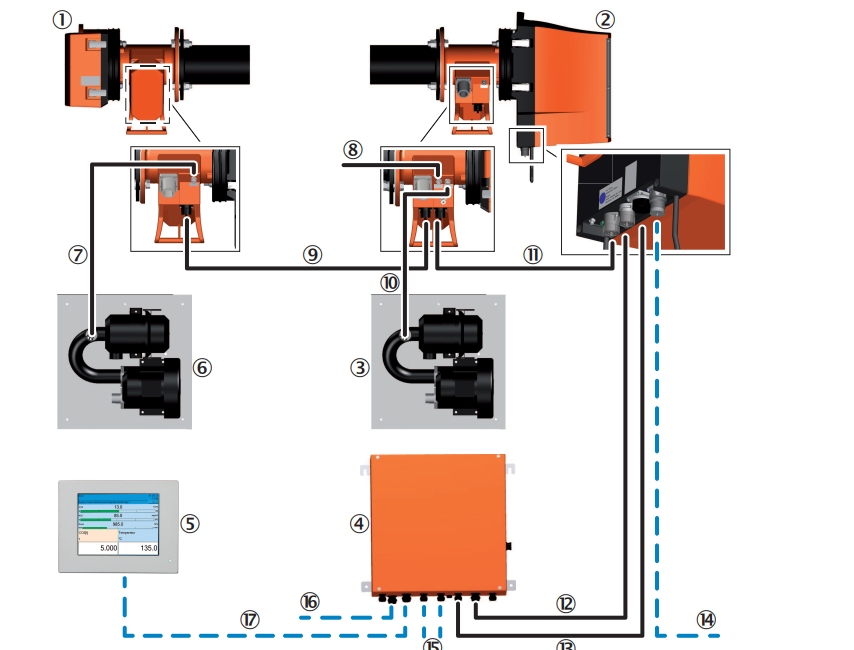

SCU control unit (for non-hazardous areas only)

Multi range calibration (additional measuring ranges for one component)

Extended gas temperature range up to 550 °C or 650 °C

LowNO2

GM32 TRS–PE system

- Description: In-situ gas analyzer for TRS monitoring in the Kraft pulping process

- Measured values: NO, NH3, SO2, CH3SH, (CH3)2S, (CH3)2S2, H2S, TRS

- Measurement principles: Chemometrical data evaluation (CDE)

- Measuring ranges:

NH3: 0 … 35 ppm / 0 … 50 ppm

NO: 0 … 40 ppm / 0 … 150 ppm

SO2: 0 … 15 ppm / 0 … 35 ppm

H2S: 0 … 35 ppm

CH3SH: 0 … 25 ppm

(CH3)2S: 0 … 20 ppm

(CH3)2S2: 0 … 15 ppm

TRS: 0 … 70 ppm

Measuring ranges refer to 1 m measuring path

Measuring ranges depend on application and device version

TRS = H2S + CH3SH (as H2S equivalent)

For device variant 7: TRS = H2S + CH3SH + (CH3)2S + 2x (CH3)2S2

Other measuring ranges on request

- Response time (t90): Gas-testable measuring probe (GPP): ≥ 120 s, Response time adjustable

- Accuracy:

NH3: ± 2 %

NO: ± 2 %

SO2: ± 0.3 ppm … ± 2 %

H2S: ± 2 %

CH3SH: ± 2 %

(CH3)2S: ± 2 %

(CH3)2S2: ± 2 %

TRS: ± 2 %

Relative to the smallest measuring range

- Ambient temperature: –20 °C … +55 °C

Temperature change maximum: ±10 °C/h

- For device variant 7: +20 °C … +30 °C

- Storage temperature: –20 °C … +55 °C

Temperature change maximum: ±10 °C/h

- Ambient humidity: ≤ 95 %, Relative humidity; non-condensing

- Electrical safety: CE

- Mounting:

Mounting flange, DN125, PN6

Mounting flange, ANSI, 5″

Test functions Internal zero and reference point check

- Options: SCU control unit

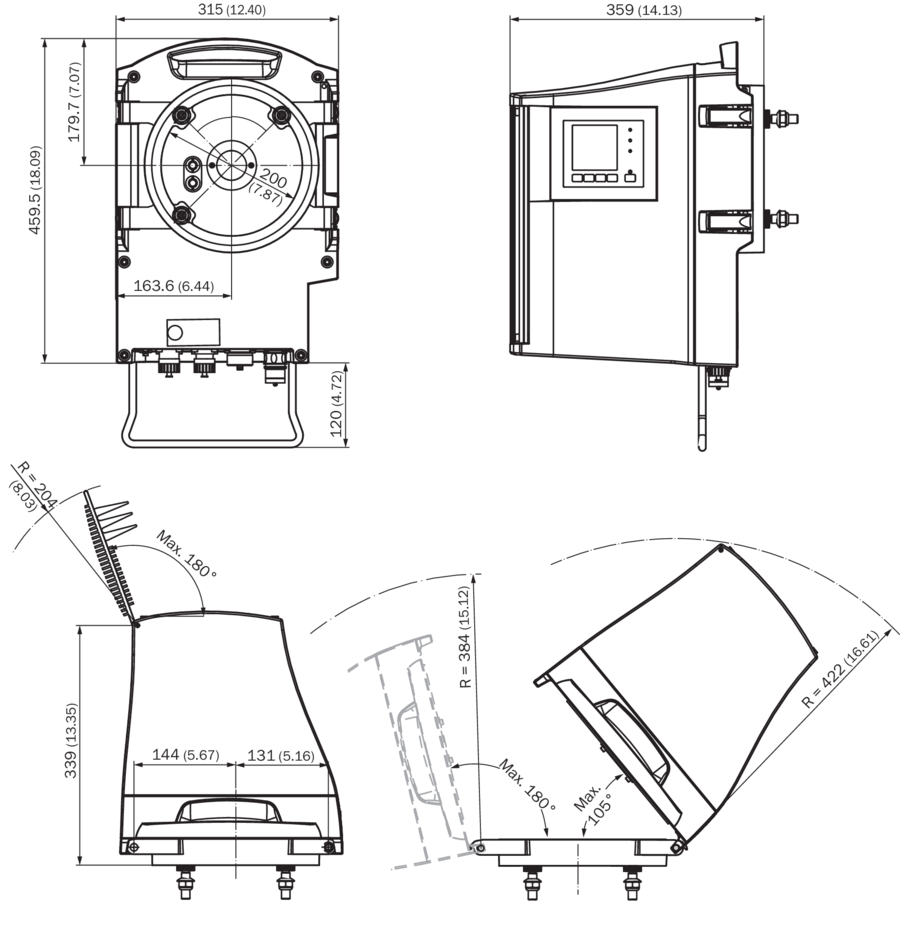

Sender/receiver unit; standard version

- Description: Analyzer unit of the measuring system

- Electrical safety: CE

- Enclosure rating: IP65 / IP69K

- Operation: Via integrated control unit

- Dimensions (W x H x D): 315 mm x 580 mm x 359 mm (for details see dimensional drawings)

- Weight: 20 kg

- Power supply:

Voltage: 24 V DC

Voltage: Supply via connection unit

Power consumption: 36 W

Sender/receiver unit; Ex-version

- Description: Analyzer unit of the measuring system

- Electrical safety: CE

- Enclosure rating: IP65 / IP69K

- Operation: Via integrated control unit

- Dimensions (W x H x D): 315 mm x 910 mm x 410 mm (for details see dimensional drawings)

- Weight : 20 kg

- Power supply:

Voltage: 24 V DC

Voltage: Supply via connection unit

Power consumption: 36 W

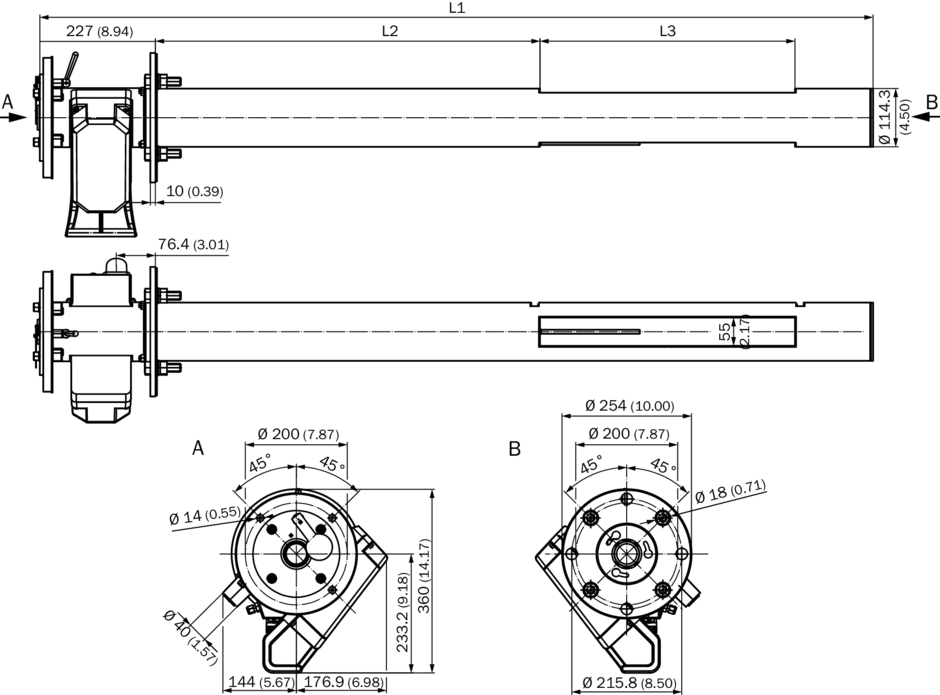

Open measuring probe (GMP)

- Description: Measuring probe in open design with integrated purge air control system

- Measuring distance: See dimensional drawings

- Accuracy:

Pressure sensor: 1 %

Temperature sensor: 1 %

- Process temperature: ≤ +550 °C

- Process pressure: –60 hPa … 30 hPa, Depending on purge air supply

- Dust load: ≤ 3 g/m³, Based on a 1 m measuring distance, depending on application

- Electrical safety: CE

- Dimensions (W x H x D): Dimensions may vary. For details, see the dimensional drawings.

- Weight: See dimensional drawings

- Material in contact with media: Stainless steel 1.4571, stainless steel 1.4539

- Power supply: Supply via sender/receiver unit

- Auxiliary gas connections: Purge air Hose nozzle 40 mm

- Integrated components:

Flow monitor for purge air monitoring

Pressure sensor (Not for Ex-version)

PT1000 temperature sensor (not for Ex-version)

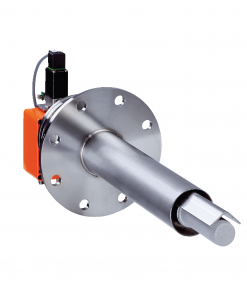

Gas-testable measuring probe (GPP)

- Description: Measuring probe with gas permeable filter element for adjustment with test gas

- Measuring distance: See dimensional drawings

- Accuracy:

Pressure sensor: 1 %

Temperature sensor: 1 %

- Process temperature:

With ceramic filter: ≤ +430 °C

Brief (max. 30 min.) up to 550 °C. At temperatures higher than 430 °C, reliable output of measured values can no longer be guaranteed.

NH3 measurement with ceramic filter: +300 °C … +430 °C

Brief (max. 30 min.) up to 550 °C. At temperatures higher than 430 °C, reliable output of measured values can no longer be guaranteed.

With Teflon filter: ≤ +200 °C

- Process pressure: –120 hPa … 200 hPa

- Dust load: ≤ 30 g/m³

- Electrical safety: CE

- Enclosure rating: IP65

- Dimensions (W x H x D): Dimensions may vary. For details, see the dimensional drawings.

- Weight : See dimensional drawings

- Material in contact with media: Stainless steel 1.4571, stainless steel 1.4539, ceramics, PTFE

- Power supply:

Voltage: 115 V AC / 230 V AC

Frequency: 50 Hz / 60 Hz

Power consumption: ≤ 150 W

- Auxiliary gas connections: Test gas, Clamp connection 1/4″

- Integrated components:

Pressure sensor

PT1000 temperature sensor

Heating of optical surfaces

Reflector unit

- Description: Reflector unit with glass triple reflector

- Measuring distance:

Cross-duct version: 0.25 m … 12 m

Flange – flange distance minus 2 x flange length

- Process temperature: ≤ +550 °C, Versions for higher temperatures on request

- Process pressure: –60 hPa … 30 hPa, Depending on purge air supply

- Dust load: ≤ 3 g/m³, Based on a 1 m measuring distance, depending on application

- Electrical safety: CE

- Enclosure rating: IP65 / IP69K

- Dimensions (W x H x D): 291 mm x 280 mm x 161 mm (for details see dimensional drawings)

- Weight : 8.5 kg

Connection unit; standard version

- Description: Serves for connection of power supply, data and signal cabling provided by the customer

- Electrical safety: CE

- Enclosure rating: IP65 / IP69K

- Analog outputs: 2 outputs, 0/4 … 22 mA, 500 Ω, Per module, extendable up to eight outputs

- Analog inputs: 2 inputs, 0/4 … 22 mA, 100 Ω

- Digital outputs: 4 outputs, 48 V AC/DC, 0.5 A, 25 W

- Digital inputs: 4 inputs, 3.9 V, 4.5 mA, 0.55 W, Per module, extendable up to eight inputs

- Communication interface:

Modbus

CAN bus

Ethernet

- Type of fieldbus integration:

TCP

RTU RS-485 (via optional interface module)

- Function: Internal system bus, Connection to SOPAS ET software or OPC server

- Number: 1

- Dimensions (W x H x D): 450 mm x 424 mm x 158 mm (for details see dimensional drawings)

- Weight : 16 kg

- Power supply:

Voltage: 100 … 250 V AC

Frequency: 50 Hz / 60 Hz

Power consumption: ≤ 260 W

Connection unit; Ex-version

- Description: Serves for connection of power supply, data and signal cabling provided by the customer

- Electrical safety: CE

- Enclosure rating: IP65 / IP69K

- Analog outputs: 2 outputs, 0/4 … 22 mA, 500 Ω, Per module, extendable up to eight outputs

- Analog inputs: 2 inputs, 0/4 … 22 mA, 100 Ω

- Digital outputs: 4 outputs, 48 V AC/DC, 0.5 A, 25 W

- Digital inputs: 4 inputs, 3.9 V, 4.5 mA, 0.55 W, Per module, extendable up to eight inputs

- Communication interface:

Modbus

CAN bus

Ethernet

- Type of fieldbus integration:

TCP

RTU RS-485 (via optional interface module)

- Function: Internal system bus, Connection to SOPAS ET software or OPC server

- Number: 1

- Dimensions (W x H x D): 679 mm x 630 mm x 158 mm (for details see dimensional drawings)

- Weight : 16 kg

- Power supply:

Voltage: 100 … 230 V AC

Frequency: 50 Hz / 60 Hz

Power consumption: ≤ 260 W

Purge air fixture; sender/receiver unit

- Description: Flange fixture for connections for purge air hose, temperature and pressure sensor

- Electrical safety: CE

- Dimensions (W x H x D): 309 mm x 364 mm x 242 mm (for details see dimensional drawings)

- Weight: 9.6 kg

- Auxiliary gas connections: Purge air, Hose nozzle 40 mm

- Electrical connections:

Purge air unit low-pressure monitor

PT1000 temperature sensor

Pressure sensor

- Integrated components:

Flow monitor for purge air monitoring

Pressure sensor

Purge air fixture; reflector unit

- Description: Flange fixture for connections for purge air hose and purge air monitoring

- Electrical safety: CE

- Dimensions (W x H x D): 309 mm x 364 mm x 242 mm (for details see dimensional drawings)

- Weight: 9.6 kg

- Auxiliary gas connections:

- Purge air: Hose nozzle 40 mm

- Electrical connections: Purge air unit low-pressure monitor

- Integrated components: Flow monitor for purge air monitoring

Pressure and temperature sensor (cross-duct version)

- Description: Pressure and temperature sensor with DN40 / PN40 mounting flange

- Accuracy:

Pressure sensor: 1 %

Temperature sensor: 1 %

- Process temperature: ≤ +500 °C

- Electrical safety: CE

- Dimensions (W x H x D): Dimensions may vary. For details, see the dimensional drawings.

- Immersion depth, PT1000 temperature sensor: 500 mm/ 1,000 mm/ 1,400 mm

- Material: Stainless steel 1.4571, steel ST37

- Scope of delivery:

Connecting cable for temperature sensor, 5 m

Connecting hose for pressure sensor, 5 m

Flange cover, including seal and screws

SLV4-2 purge air unit, 2BH1300, 3-ph

- Description: Unit to provide dust-free air for flushing of optical surfaces

- Gas flow rate: 38 m³/h … 63 m³/h, At 30 hPa counter pressure, depending on low pressure inside the filter

- Ambient temperature: –40 °C … +55 °C

- Electrical safety: CE

- Enclosure rating: IP54

- Dimensions (W x H x D): 550 mm x 550 mm x 258 mm (for details see dimensional drawings)

- Weight: 18 kg

- Power supply: Three-phase current

Δ: 200 … 240 V, 50 Hz, 2,6 A, 400 W

Y: 345 … 415 V, 50 Hz, 1,5 A, 400 W

Δ: 200 … 275 V, 60 Hz, 2,6 A, 500 W

Y: 380 … 480 V, 60 Hz, 1,5 A, 500 W

Δ: 270 … 330 V, 50 Hz, 2,0 A, 400 W

Y: 465 … 570 V, 50 Hz, 1,16 A, 400 W

Δ: 290 … 360 V, 60 Hz, 2,1 A, 500 W

Y: 500 … 600 V, 60 Hz, 1,26 A, 500 W

Δ: 230 V, 50 Hz, 2,7 A, 370 W

Δ: 115 V, 60 Hz, 3,0 A, 450 W

Δ: 220 … 270 V, 50 Hz, 2,5 A, 400 W

Y: 380 … 465 V, 50 Hz, 1,45 A, 400 W

Δ: 240 … 290 V, 60 Hz, 2,6 A, 500 W

Y: 415 … 500 V, 60 Hz, 1,55 A, 500 W

- Auxiliary gas connections:

Purge air: 40 mm

Test functions Pressure switch (switching point –35 hPa)

- Integrated components: 2-step air filter, type Europiclon, dust capacity 200 g

SLV6-1 purge air unit, 2SH1300, ATEX 3G

- Description: Unit to provide dust-free air for flushing of optical surfaces; for potentially explosive atmospheres

- Gas flow rate: 38 m³/h … 63 m³/h, At 30 hPa counter pressure, depending on low pressure inside the filter

- Ambient temperature: –20 °C … +40 °C

- Ex-approvals

- ATEX Ex II 3G c T3

- Electrical safety: CE

- Enclosure rating: IP54

- Dimensions (W x H x D): 550 mm x 681 mm x 287 mm (for details see dimensional drawings)

- Weight: 28 kg

- Power supply: Three-phase current

3-phase: 230 V/400 V, 50 Hz

3-phase: 460 V, 60 Hz

- Auxiliary gas connections:

Purge air: 40 mm

Test functions Pressure switch (switching point –35 hPa)

- Integrated components: 2-step air filter, type Europiclon, dust capacity 200 g