PHYSICAL AND CHEMICAL PROPERTIES OF INDUSTRIAL FIBRES

| Aramid | Polyester | Polyamide | Steel | |

| Density g/cm2 | 1,44 | 1,38 | 1,14 | 7,85 |

| Melting point °C | >500 | 260 | 255 | 1600 |

| Tenacity mN/tex | 1950 | 820 | 820 | 330 |

| Tensile strenght N/mm2 | 2800 | 1130 | 935 | 2550 |

| Elongation at break % | 3,3 | 13 | 20 | 2,5 |

| Max stretching at working tension % | 0,5 | 1,5 | 2,5 | 0,3 |

| Heat degradation % (after 48h, 200 °C) | 90 | 55 | 45 | 100 |

Bolt values show the main advantages of aramid in comparison with other fibers:

➢ Superior strength/weight ratio

➢ High working temperature

➢ Density similar to textile fibres

➢ Tensile and elongation similar to steel cord

➢ Superior flame resistance

COMPARATIVE TABLE

| Aramid | Polyester | Polyamide | Steel | |

| Tensile strength (load/section) | *** | * | * | *** |

| Tenacity (load/weight) | *** | ** | ** | * |

| Modulus | *** | ** | * | *** |

| Temperature resistance | ** | * | * | *** |

| Flammability | ** | * | * | *** |

| Longitudinal flexibility | *** | ** | ** | * |

| Troughability | *** | * | ** | *** |

| Impact | ** | *** | *** | * |

| Low belt weight | *** | ** | ** | * |

| Low belt thickness | *** | * | * | ** |

| Corrosion | *** | *** | *** | * |

| Amagnetic properties | *** | *** | *** | * |

* Fair ** Good *** Excellent

Technical Data

| Fabric style | KN/m | 630 | 800 | 1000 | 1250 | 1400 | 1600 | 1800 | 2000 | 2500 |

| Belt style | KN/m | 630 | 800 | 1000 | 1250 | 1400 | 1600 | 1800 | 2000 | 2500 |

| Working tension | KN/m | 80 | 100 | 125 | 160 | 175 | 200 | 225 | 250 | 315 |

| Carcass weight | Kg/m2 | 2,3 | 2,4 | 2,9 | 3,4 | 3,5 | 3,6 | 4,1 | 4,3 | 4,7 |

| Carcass thickness | mm | 1,90 | 2,10 | 2,60 | 2,90 | 3,35 | 3,35 | 3,40 | 3,45 | 3,50 |

DESIGN VALUES AND SAFETY FACTORS

| ARABELT® | Steel cord | EP belt | |

| Tensile strength (%) | 100 | 100 | 100 |

| Working tension (%) | 12,5 | 12,5 | 10 |

| Peak tension (starting) (%) | 16,7 | 16,7 | 12,5 |

| Safety factor in ordinary use | 8 | 8 | 10 |

| Safety factor at starting | 6 | 6 | 8 |

Safety factors similar to steel cord belts are acceptable thanks to the monoply straight warp construction of ARABELT®, more similar to steel cord than textile costruction.

MINIMUM RECOMMENDED PULLEY DIAMETER mm

| Belt style KN/m |

100% – 60% of RMBT | 60% – 30% of RMBT | ||

| Drive pulley | Tail & Snub

pulleys |

Drive pulley | Tail & Snub

pulleys |

|

| 630 | 315 | 250 | 250 | 250 |

| 800 | 500 | 315 | 315 | 250 |

| 1000 | 500 | 400 | 400 | 315 |

| 1250 | 630 | 500 | 500 | 400 |

| 1400 | 800 | 630 | 630 | 500 |

| 1600 | 800 | 630 | 630 | 500 |

| 1800 | 800 | 630 | 630 | 500 |

| 2000 | 1000 | 800 | 800 | 630 |

| 2500 | 1250 | 1000 | 1000 | 800 |

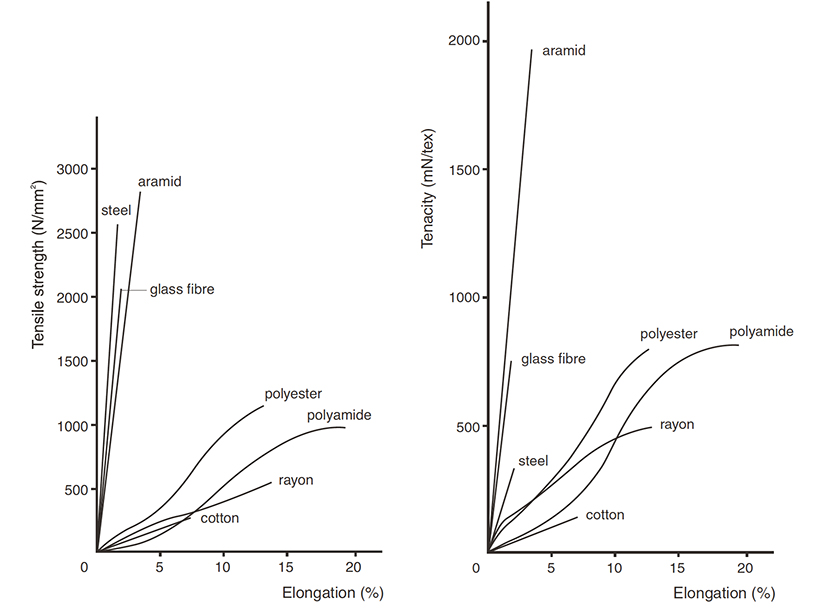

COMPARATIVE GRAPHICS

Graphics show the difference of elastic characteristics between aramid and other fibres, commonly used in conveyor belt production.

The extreme differences between aramid and standard textile fibres, natural or syntetic are evident.

The history of conveyor belts is represented by these curves starting from cotton with very poor mechanical characteristics, soon after from rayon, polyamide and polyester with always better performances. Aramid, a sintetic fibre with same origin of polyester and polyamide, shows total different characteristics, with very low elongation, high elastic modulus (curve slope) and superior specific tensile strength.

Two similar graphics are represented in order to explain one of the most important properties of aramid: density. In the left graphic, we observe that aramid and steel seem to have similar characteristics. In mechanical terms, this is true but for conveyor belts the weight is a fundamental parameter as it defines the power necessary to assure the movement.

So, looking the graphic on the right, we notice big differences between aramid and steel: this is due to their weight ratio (more than 5:1). This very low density of aramid assures a very high tenacity (ratio strength/weight): being equal the tensile strength, the weight of aramid resistant fabric is lower than steel cord carcass (see: Steel Cord Conveyor Belts).

Hợp chất bao phủ và dịch vụ cụ thể

ABRASION SERVICE

- CL (L grade ISO 10247) Standardmwear resistant compound.

- CL is a cover rubber recommended for all ground applications and for the majority of materials, where resistance to abrasion is required. Conveyor belts with CL compound are suitable to handle heavy and/or abrasive materials such as gravel, stone, coal, cement.

- EC (D grade ISO 10247) Extra wear bresistant compound.

- EC is a superior quality cover rubber, especially designed where maximum resistance to abrasion is required. The characteristics of resistance to cut, tear and ozone cracking, together with long duration, improve the quality of this cover. EC is expressly designed for steel works and iron minings; however, it is also recommended for heavy lump ore, coke, salt, limestone.

- SC (H grade ISO 10247) Superior cutting resistant compound.

- SC is a cover rubber designed for specific use when the resistance to cut and tear is the most important requirement. SC also guarantees high abrasion resistance. Main applications are quartz and cullet conveyance.

TỰ CHỮA CHÁY

- BS Hợp chất tự động dập tắt.

- BS là một loại cao su che phủ được thiết kế để phục vụ cho cả ứng dụng ngầm và trên mặt đất, nơi an toàn là cơ bản và nguy cơ hỏa hoạn cao. Nó được khuyến nghị đặc biệt cho các ứng dụng than và kali. là hợp chất chống tĩnh điện và chống tĩnh điện tự động, BS được thiết kế theo ISO 340 và ISO 284 hoặc tương đương.

- Hợp chất chống cháy và dầu tự động AG.

- AG là một hợp chất nitrile thích hợp cho băng tải và hệ thống thang máy gầu của các thiết bị đầu cuối và silo chứa ngũ cốc. Cao su che AG cung cấp khả năng chống dầu vượt trội đối với dầu thực vật và mỡ động vật; nó cũng tự động dập tắt và chống tĩnh điện theo ISO 340 và ISO 284 hoặc tương đương để đảm bảo an toàn cao cho nhà máy băng tải.

SELF EXTINGUISH

- BS Autoextinguish compound.

- BS is a cover rubber designed to service both underground and above ground application where safety is fundamental and fire risk is high. It is recommended in particular for coal and potash applications. as auto estinguish and antistatic compound, BS is designed according ISO 340 and ISO 284 or equivalent.

- AG Autoextinguish and oil resistant compound.

- AG is a nitrile compound suitable for conveyor belts and bucket elevator systems of cereal terminals and silos. AG cover rubber provides superior resistances to vegetable oils and animal fats; it is also autoextinguish and antistatic according to ISO 340 and ISO 284 or equivalent in order to guarantee high safety to the conveyor plant.

OIL SERVICE

- OH High oil resistance compound.

- OH is a premium quality cover rubber with maximum resistance to oils and characterized by low volume variations after immersion in highly aggressive mineral oils. OH is expressly realized for belts conveying materials sodden by mineral oils, as for example the mechanical manufacturing rejects.

- OM Vegetable oil resistance compound.

- OM is a cover rubber that guarantees a good belt resistance against the chemically aggressive effects due to the transport of materials with moderate oil presence, like corn, fertilizers and general vegetable oily materials.

- OM is expressly designed to resist the terpene of wooden chips and to convey solid urban waste materials.

HEAT SERVICE

CX High temperature resistance.

CX is a rubber compound assuring a medium degree of abrasion resistance; it is formulated for continuous

service at temperature of 130 °C with peacks of 150 °C

TX Superior temperature resistance.

TX is a cover rubber that assures the maximum heat resistance for a rubber compound. It is designed to resist at maximum working temperature of 200 °C with peack of 300 °C.

All type of conveyor belts produced by SIG SpA are realized according to ISO standard; furthermore they meet also the requirements of equivalent UNI, DIN, BS, NF, ASTM and RMA standards.

Table

|

Service & resistance |

Abrasion resistant | Selfextinguish | Oil resistant |

Heat |

|||||

| CL | EC | SC | BS | AG | OM | OH | CX | TX | |

| Abrasion | XXX | XXXX | XXX | XX | X | X | X | XX | XXX |

| Cut & tear | XX | XXX | XXXX | XX | XX | XX | XX | XX | XX |

| Fire | N.A. | N.A. | N.A. | XXXX | XXXX | N.A. | N.A. | N.A. | N.A. |

| Conductivity | XXXX | XXXX | XXXX | XXXX | XXXX | XXXX | XXXX | XXXX | XXXX |

| Animal & vegetable oils | N.A. | N.A. | N.A. | N.A. | XXXX | XXXX | XXXX | N.A. | N.A. |

| Mineral oils | N.A. | N.A. | N.A. | N.A. | XXXX | XX | XXXX | N.A. | N.A. |

| Heat | XX | XX | XX | XX | XX | XX | XX | XXX | XXXX |

N.A. Not applicable; X fair; XX good; XXX very good; XXXX excellent.

TEMPERATURE RESISTANCE °C

|

Service & resistance |

Abrasion resistant | Selfextinguish | Oil resistant |

Heat |

|||||

| CL | EC | SC | BS | AG | OM | OH | CX | TX | |

| High Temp. (fines) | 70 | 70 | 70 | 70 | 80 | 70 | 80 | 130 | 180 |

| High Temp. (coarse) | 90 | 90 | 90 | 90 | 100 | 90 | 100 | 150 | 200 |

| Low Temperature | -40 | -40 | -40 | -30 | -25 | -40 | -25 | -30 | -30 |

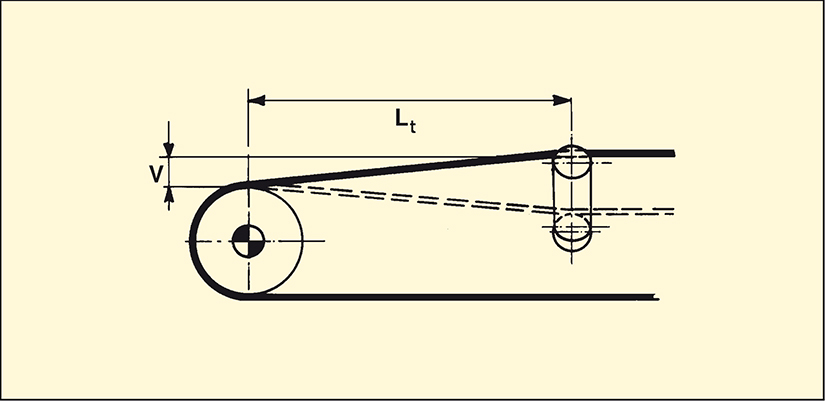

Transition Distance

- The transition distance is the length of the section between head or tail pulley and the first troughing idler. In some cases, intermediate idlers are placed along the transition distance to favour the passage of the belt from the flat to the trough shape.

- These conveyor sections are the most critical points of the whole plant as the elastic performaces of the belt during the time depend on them. If the transition distance is not correctly designed, high overtensions on the edges and abnormal compressions along the central axis of the belt are generated.

- Such phenomenons are the cause of unexpected defects, sometimes attributed by mistake to the belt as wave on the edges and longitudinal fold of the belt carcass.

- These considerations are extremely important for ARABELT® because of its elastic modulus, much higher than the one of other syntetic products (polyester and nylon), but quite similar to the values of steel.

- In this case, the application of ARABELT® on plant designed for standard EP belts could result in a early damaging, expecially of the edges.

- According to the recommendation of the international standard ISO 5293/81, the calculation of the transition distance is performed in order to prevent belt centre from buckling and edge tension from exceeding 130% of the maximum recommended belt tension (RMBT).

These conditions can be respected adopting the following formula: Lt = 18,71 x V

When the belt is not used at 100% of RMBT, the transition distance can be reduced according to the following table:

|

%RMBT |

90% | 80% | 70% | <60% |

| Lt multiplier factor | 0,93 | 0,82 | 0,74 |

0,71 |

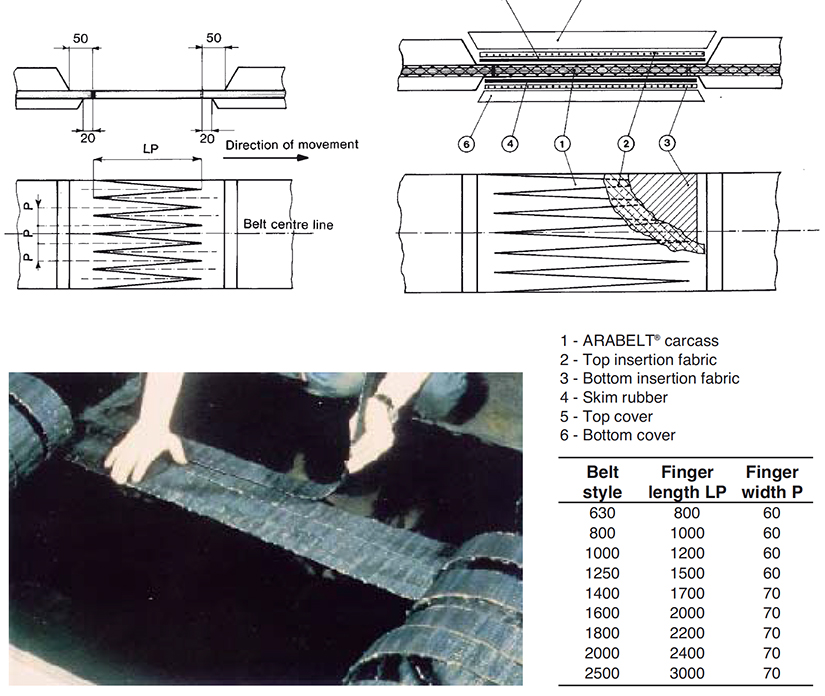

Splicing Method

- One of the advantages of ARABELT® is the easy system of splicing and repair: only ordinary equipments used for textile belts are necessary and the required time is less than the one for steel cord belts.

- We recommend the finger method shown in this page to avoid any transversal and lengthwise stiffening. This is fondamental to allow the running with small pulley diameter and sets of idlers with high inclination (up to 45°) without any dangerous overstress on the splice.

- The first step for the preparation of the joint is the removal of both the covers of the two ends of the belt. – Refere to the table and the drawings for the dimension of these areas. –

- Then it is necessary to draw and cut the fingers that will realize the joint.

- The belt must then be lined up and the splice elements coupled. This operation needs to fix the belt ends, turn the fingers over to put in position rubber sheet for bottom cover, bottom insertion fabric and skim rubber. All these elements must be treated with rubber solution and rolled together to obtain the best adhesion. Then fingers must be positioned in the final position, starting from the centre towards the edges. The splice is completed with the application of skim rubber, top insertion fabric and bottom cover.

- The vulcanization process follows the same procedure used for standard fabric belts. As the final strength of the splice depends on the tearing resistance and adhesion of the skim rubber placed between fingers and insert fabric, we strongly recommend the use of our products.

|

Belt style |

Finger lenght LP |

Finger width P |

|

630 |

800 | 60 |

|

800 |

1000 | 60 |

|

1000 |

1200 | 60 |

|

1250 |

1500 | 60 |

|

1400 |

1700 |

70 |

| 1600 | 2000 |

70 |

| 1800 | 2200 |

70 |

| 2000 | 2400 |

70 |

| 2500 | 3000 |

70 |