PULS DIN rail power supplies beat in the heart of the best machines. For decades machine builders trust in the reliability and power reserves of our products

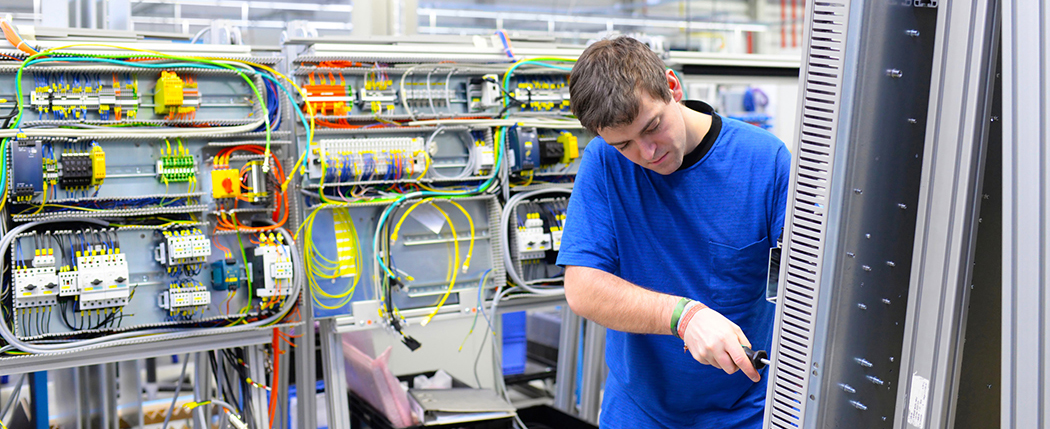

The deployment of power supplies in machine building applications are extremely varied and are subject to a broad range of requirements. PULS offers a wide range of products that can cope with all these requirements: Power supplies (AC 1-phase or 3-phase, and with DC input), DC-UPS, buffer modules and redundancy modules. Modern machine building is a fascinating combination of electronics and mechanics.

Smallest size enables limitless applications in machine building

Machine controls are becoming ever more complex, meaning that increased functionality is required in the control cabinet. The size is also an important criterion for the design engineer and despite ever more functions, the goal is for the cabinet to become even smaller. PULS supplies the world’s smallest DIN-rail switch-mode power supplies.

Highest demands in terms of reliability and service life fulfilled

The electronic control is the heart of every machine and consequently any failures here result in expensive production downtime. This means the power supply must fulfil the highest demands in terms of quality and life – and all this under the most challenging load and ambient conditions.

PULS guarantees maximum service life values, and provides a 3-year warranty.

Power reserves lead to higher efficiency and savings in machine building

Depending on the range, PULS guarantees a PowerBoost of up to 20% or a BonusPower of 50%. Larger power reserves help start heavy loads such as DC motors or capacitive loads with ease.

Typical applications for PULS products in machine building

-

- Tooling machines

- Packaging industry

- Textile industry

- Laser tools

- Printing industry

- Transport and warehouse logistics systems

- Food industry

- Security systems

- Railway applications

Application example: The laser

The laser is the universal tool for cutting, welding, marking, drilling, hardening, as well as for structural processing of surfaces. It works without contact and wearout. Lasers only face a low thermal influence and there is almost no deformation of the components because of heat. Therefore, costs for reworking will normally not occur.

The world leader in this technology relies on the DIN-rail power supplies of PULS. The most important points for this customer are the consistent high quality, high reliability, the highest efficiency and guaranteed availability.

The laser tool and all components should spend very little power; therefore, power supplies with a very high efficiency are required. PULS also builds the smallest and the most lightweight power supplies.

Laser technology is used in various industries. Machining of gears and precision parts, exhaust components, sensors, control components, pipes, profiles, deep-drawn parts – there is no limit for applications and new opportunities.