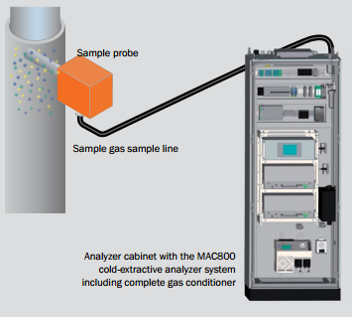

GMS800 system

- Measured values: Ar, CH4, CH3OH, C2H2, C2H2F4, C2H4, C3H6, C3H8, C4H6, Cl2, CO, CO2, COCl2, COS, CS2, H2, H2S, He, NH3, NO, N2O, NO2, O2, SF6, SO2, other components on request

- Performance-tested measurands: CH4, CO, CO2, NO, NO2, O2, SO2

- Gas flow rate: 30 l/h … 60 l/h

- Sample gas temperature: Analyzer inlet 0 °C … +45 °C

- Process pressure:

Hosed gas lines: –200 hPa … 300 hPa

Tubed gas lines: –200 hPa … 1,000 hPa

- Process gas humidity: Non-condensing

- Dust load: Free of dust and aerosols

- Ambient temperature: +5 °C … +45 °C

- Storage temperature: –20 °C … +70 °C

- Ambient pressure: 700 hPa … 1,200 hPa

- Geographical altitude: + 2,500 m (above mean sea level)

- Ambient humidity: 20 % … 90 %, Relative humidity; non-condensing

- Electrical safety: CE

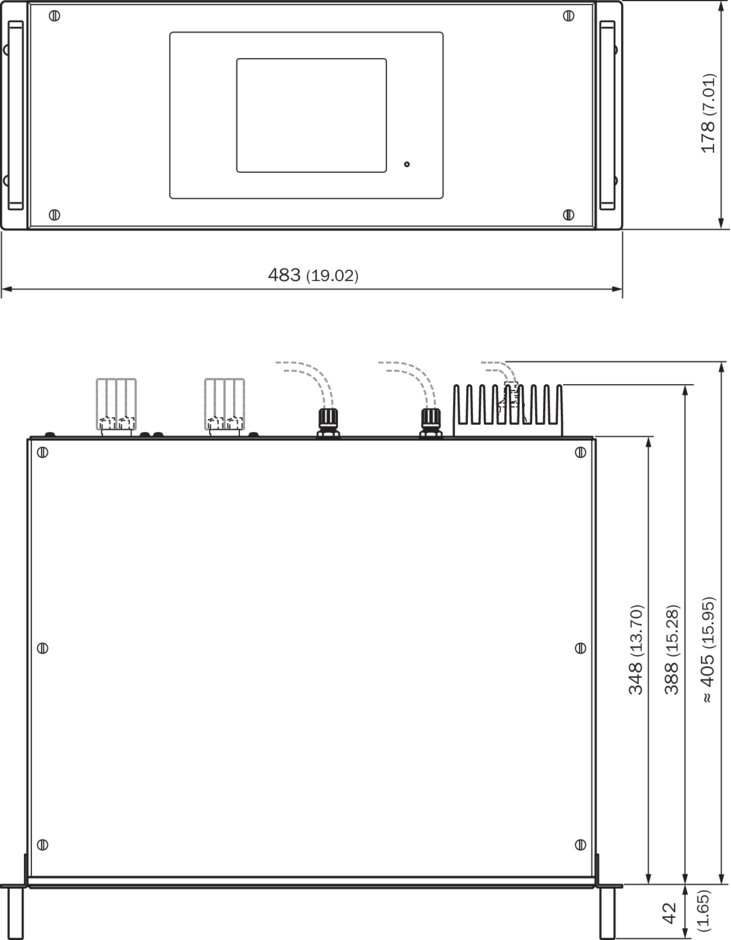

GMS810 design

- Description: 19″ rack enclosure with 4 rack units, for integration in cabinets

- Electrical safety: CE

- Enclosure rating: IP40

- Dimensions (W x H x D): 483 mm x 178 mm x 388 mm (for details see dimensional drawings)

- Weight : 9 kg … 20 kg, Depending on configuration

- Power supply:

Voltage: 93 … 132 V AC / 186 … 264 V AC / 210 … 370 V AC

Frequency: 47 … 63 Hz

Power consumption: ≤ 300 W

- Sample gas connections: PVDF bulkhead fitting: for hose 6 x 1 mm

- Auxiliary gas connections: For purge gas or flowing reference gas: option

- Options: Gas connections: Swagelok 6 mm or Swagelok 1/4″

GMS811 design

- Description: 19″ rack enclosure with 4 rack units, for usage with separate control unit (BCU), for integration in cabinets

- Electrical safety: CE

- Enclosure rating: IP40

- Dimensions (W x H x D): 483 mm x 178 mm x 388 mm (for details see dimensional drawings)

- Weight: 9 kg … 20 kg (Depending on configuration)

- Power supply:

Voltage: 93 … 132 V AC / 186 … 264 V AC / 210 … 370 V AC

Frequency: 47 … 63 Hz

Power consumption: ≤ 300 W

- Sample gas connections: PVDF bulkhead fitting: for hose 6 x 1 mm

- Auxiliary gas connections: For purge gas or flowing reference gas: option

- Options: Gas connections Swagelok 6 mm or Swagelok 1/4″

GMS820P design

- Description: Flame-proof enclosure for use in Ex-zone 1 areas

- Ex-approvals:

IECEx: Ex db eb [ia] IIC T6

ATEX: II 2G Ex db eb [ia] IIC T6 Gb

II 2G Ex db eb IIC T6 Gb

- Electrical safety: CE

- Enclosure rating: IP65

- Dimensions (W x H x D): 790 mm x 590 mm x 353 mm (for details see dimensional drawings)

- Weight : 140 kg … 150 kg (Depending on configuration)

- Power supply:

Voltage: 93 … 132 V AC / 186 … 264 V AC / 210 … 370 V AC

Frequency: 47 … 63 Hz

Power consumption: ≤ 300 W

- Sample gas connections: Inside thread G1/4″

- Auxiliary gas connections: For purge gas or flowing reference gas: option

- Options: Gas connections Swagelok 6 mm or Swagelok 1/4″

GMS840 design

- Description: Closed sheet steel housing for wall mounting for use indoors

- Ambient temperature: +5 °C … +45 °C

- Storage temperature: –10 °C … +70 °C

- Ambient humidity: 10 % … 95 %, Non-condensing

- Ex-approvals:

IECEx: GMS841: Ex nA nC IIC T4 Gc

GMS841: Ex nA nC [ia Ga] IIC T4 Gc

ATEX: GMS841: II 3G Ex nA nC IIC T4 Gc

GMS841: II 3G Ex nA nC [ia Ga] IIC T4 Gc

NEC/CEC (US/CA): GMS842: Class I, Division 2, Group A, B, C, D T4

GMS842: Class I, Zone 2

GMS842: Ex nA nC IIC T4 Gc

GMS842: Ex nA nC [ia Ga] IIC T4 Gc

GMS842: AEx nA nC IIC T4 Gc

GMS842: AEx nA nC [ia Ga] IIC T4 Gc

- Electrical safety: CE

- Enclosure rating: IP66 / NEMA 4x

- Dimensions (W x H x D): 522 mm x 475 mm x 478 mm (for details see dimensional drawings)

- Weight: ≤ 30 kg (Depending on configuration)

- Power supply:

Voltage: GMS840: 85 … 264 V AC

Frequency: 47 … 63 Hz

Current consumption: ≤ 10 A

Power consumption: ≤ 300 W (Depending on configuration)

- Sample gas connections:

Inside thread G1/4″: for screw-in fittings

Swagelok 6 mm: stainless steel, for metal tube

Swagelok 1/4″: stainless steel, for metal tube

PVDF compression fitting: for hose 6 x 1 mm

DEFOR analyzer module

- Description: UV gas analyzer for simultaneous measurement of up to 3 gas components

- Measurement principles: NDUV spectroscopy, UVRA spectroscopy

- Measuring ranges:

Cl2: 0 … 125 ppm / 0 … 100 Vol.-%

COS: 0 … 250 ppm / 0 … 100 Vol.-%

CS2: 0 … 50 ppm / 0 … 30 Vol.-%

H2S: 0 … 25 ppm / 0 … 100 Vol.-%

NH3: 0 … 50 ppm / 0 … 100 Vol.-%

NO: 0 … 10 ppm / 0 … 100 Vol.-%

NO2: 0 … 50 ppm / 0 … 100 Vol.-%

NO2(*): 0 … 10 ppm / 0 … 100 Vol.-%

SO2: 0 … 25 ppm / 0 … 100 Vol.-%

SO2(*) 0 … 10 ppm / 0 … 100 Vol.-%

(*) NO2, SO2: Smallest measuring range with daily adjustment of zero point and operation in an air-conditioned environment with temperature stability of ± 2 °C

- Certified measuring ranges:

NO: 0 … 50 mg/m³ / 0 … 1,000 mg/m³ / 0 … 2,000 mg/m³

NO2: 0 … 50 mg/m³ / 0 … 500 mg/m³

SO2: 0 … 75 mg/m³ / 0 … 287 mg/m³ / 0 … 2,000 mg/m³

- Response time (t90): 4 s, Typical at 60 l/h (depending on cell length and gas flow)

- Sensitivity drift : ≤ 1 %: of measuring range full scale per week

- Zero point drift: ≤ 1 %: of measuring range full scale per week

- Measuring ranges smaller than 2 x smallest measuring range ≤ 2 %: of measuring range full scale per week

- NO, NO2, SO2 : ≤ 1 %: of smallest measuring range per day

- Conformities: Approved for plants requiring approval

2001/80/EC (13. BImSchV)

2000/76/EC (17. BImSchV)

27. BImSchV

TA-Luft (Prevention of Air Pollution)

EN 15267

EN 14181

MCERTS

- Corrective functions: Manual or automatic adjustment with test gases or adjustment cell

- Test functions: Self test and fault diagnosis

MULTOR analyzer module

- Description: Multi-component NDIR analyzer for continuous measurement of up to 3 IR-absorbing gases and H2O for internal interference sensitivity correction

- Measurement principles: NDIR spectroscopy

- Measuring ranges:

CH4: 0 … 400 ppm / 0 … 100 Vol.-%

CO: 0 … 160 ppm / 0 … 100 Vol.-%

CO2: 0 … 100 ppm / 0 … 100 Vol.-%

NO: 0 … 190 ppm / 0 … 100 Vol.-%

SO2: 0 … 90 ppm / 0 … 100 Vol.-%

- Certified measuring ranges:

CH4: 0 … 286 mg/m³ / 0 … 500 mg/m³

CO: 0 … 200 mg/m³ / 0 … 2,000 mg/m³

CO2: 0 … 25 Vol.-%

NO: 0 … 250 mg/m³ / 0 … 2,500 mg/m³

SO2: 0 … 250 mg/m³ / 0 … 2,000 mg/m³

- Response time (t90): ≤ 25 s, At 60 l/h, depending on cuvette length, gas flow and number of measuring components

- Sensitivity drift : ≤ 1 % of measuring range full scale per week

- Zero point drift: ≤ 1 % of smallest measuring range per week

- Measuring ranges smaller than 2 x smallest measuring range ≤ 2 % of smallest measuring range per week

- Conformities: Approved for plants requiring approval

2001/80/EC (13. BImSchV)

2000/76/EC (17. BImSchV)

27. BImSchV

TA-Luft (Prevention of Air Pollution)

EN 15267

EN 14181

MCERTS

- Corrective functions: Manual or automatic adjustment with test gases or adjustment cell

- Test functions: Self test and fault diagnosis

OXOR-E analyzer module

- Description: Determination of oxygen content using an electrochemical cell

- Measurement principles: Electrochemical cell

- Measuring ranges O2: 0 … 10 Vol.-% / 0 … 25 Vol.-%

- Certified measuring ranges: O2: 0 … 25 Vol.-%

- Response time (t90): 20 s, Typical at 60 l/h (depending on gas flow)

- Sensitivity drift : ≤ 2 % of measuring range full scale per week

- Zero point drift: ≤ 2 %: of smallest measuring range per month

- Process pressure: Analyzer inlet –200 hPa … 300 hPa, Relative

- Conformities: Approved for plants requiring approval

2001/80/EC (13. BImSchV)

2000/76/EC (17. BImSchV)

27. BImSchV

TA-Luft (Prevention of Air Pollution)

EN 15267

EN 14181

MCERTS

- Corrective functions: Manual or automated adjustment with test gases

- Test functions: Self test and fault diagnosis

OXOR-P analyzer module

- Description: Accurate oxygen analyzer which operates according to the paramagnetic measurement principle

- Measurement principles: Paramagnetic dumbbell principle

- Measuring ranges O2: 0 … 3 Vol.-% / 0 … 100 Vol.-%

- Optional: smallest measuring range 0 … 1 vol%

- Certified measuring ranges O2: 0 … 25 Vol.-%

- Response time (t90): ≤ 4 s, At a gas flow of 60 l/h

- Sensitivity drift : ≤ 1 % of measuring range full scale per week

- Zero point drift: ≤ 1 % of smallest measuring range per week

- Measuring ranges smaller 5 vol% ≤ 0.05 Vol.-%: per week

- Conformities: Approved for plants requiring approval

2001/80/EC (13. BImSchV)

2000/76/EC (17. BImSchV)

27. BImSchV

TA-Luft (Prevention of Air Pollution)

EN 15267

EN 14181

MCERTS

- Corrective functions: Manual or automated adjustment with test gases

- Test functions: Self test and fault diagnosis

- Remark: Special versions with highly solvent-resistant or highly corrosion-resistant measuring cells available

THERMOR analyzer module

- Description: Heat conductivity analyzer for the determination of concentrations in binary or quasi-binary gas mixtures

- Measurement principles: Thermal conductivity measurement

- Measuring ranges:

Ar in N2: 0 … 10 Vol.-% / 0 … 100 Vol.-%

Ar in O2: 0 … 10 Vol.-% / 0 … 100 Vol.-%

CH4 in biogas: 0 … 60 Vol.-% / 0 … 100 Vol.-%

CO2 in air: 0 … 10 Vol.-% / 0 … 100 Vol.-%

H2 in Ar: 0 … 1 Vol.-% / 0 … 100 Vol.-%

H2 in CH4: 0 … 1 Vol.-% / 0 … 100 Vol.-%

H2 in CO2: 0 … 1 Vol.-% / 0 … 100 Vol.-%

H2 in blast furnace gas: 0 … 1 Vol.-% / 0 … 100 Vol.-%

H2 in N2: 0 … 1 Vol.-% / 0 … 100 Vol.-%

He in N2: 0 … 2 Vol.-% / 0 … 100 Vol.-%

NH3 in CO2: 0 … 15 Vol.-% / 0 … 100 Vol.-%

NH3 in air: 0 … 15 Vol.-% / 0 … 100 Vol.-%

- Response time (t90): ≤ 20 s, At a gas flow of 60 l/h

- Sensitivity drift : ≤ 1 % of measuring range full scale per week

- Zero point drift: ≤ 1 % of smallest measuring range per week

- Measuring ranges smaller than 2 x smallest measuring range ≤ 2 %: of smallest measuring range per week

- Corrective functions: Manual or automated adjustment with test gases

- Test functions: Self test and fault diagnosis

UNOR analyzer module:

- Description: Highly selective NDIR analyzer for continuous measurement of almost any gas component which absorbs in the infra-red spectral range

- Measurement principles: NDIR spectroscopy

- Measuring ranges:

C2H2: 0 … 300 ppm / 0 … 100 Vol.-%

C2H2F4: 0 … 100 ppm / 0 … 100 Vol.-%

C2H4: 0 … 300 ppm / 0 … 100 Vol.-%

N2O: 0 … 25 ppm / 0 … 100 Vol.-%

NO: 0 … 75 ppm / 0 … 100 Vol.-%

NH3: 0 … 300 ppm / 0 … 100 Vol.-%

C3H6: 0 … 300 ppm / 0 … 100 Vol.-%

C3H8: 0 … 100 ppm / 0 … 100 Vol.-%

C4H6: 0 … 5,000 ppm / 0 … 20 Vol.-%

CH4: 0 … 70 ppm / 0 … 100 Vol.-%

CH3OH : 0 … 150 ppm / 0 … 10 Vol.-%

CO: 0 … 20 ppm / 0 … 100 Vol.-%

CO+CO2: 0 … 50 ppm / 0 … 100 Vol.-%

CO2: 0 … 10 ppm / 0 … 100 Vol.-%

COCl2: 0 … 200 ppm / 0 … 10 Vol.-%

SF6: 0 … 50 ppm / 0 … 100 Vol.-%

SO2: 0 … 26 ppm / 0 … 100 Vol.-%

More than 60 measuring components available

- Certified measuring ranges:

CO: 0 … 75 mg/m³ / 0 … 750 mg/m³ / 0 … 3,000 mg/m³

CO2: 0 … 25 Vol.-%

N2O: 0 … 50 mg/m³ / 0 … 500 mg/m³

NO: 0 … 100 mg/m³ / 0 … 1,000 mg/m³ / 0 … 2,000 mg/m³

SO2: 0 … 75 mg/m³ / 0 … 287 mg/m³ / 0 … 2,000 mg/m³

NOX: 0 … 100 mg/m³ / 0 … 1,000 mg/m³ / 0 … 2,000 mg/m³

CH4: 0 … 50 mg/m³ / 0 … 500 mg/m³

- Response time (t90): 3 s, Typical at 60 l/h (depending on cell length and gas flow)

- Sensitivity drift : ≤ 1 % of measuring range full scale per week

- Zero point drift: ≤ 1 % of smallest measuring range per week

- Measuring ranges smaller than 2 x smallest measuring range ≤ 2 %: of smallest measuring range per week

- Conformities: Approved for plants requiring approval

2001/80/EC (13. BImSchV)

2000/76/EC (17. BImSchV)

27. BImSchV

TA-Luft (Prevention of Air Pollution)

EN 15267

EN 14181

MCERTS

- Corrective functions: Manual or automatic adjustment with test gases or adjustment cell

- Test functions: Self test and fault diagnosis

BCU control unit

- Communication interface: Modbus/ Ethernet

- Type of fieldbus integration: TCP/ RTU RS-485

- Function: Connection to SOPAS ET software or OPC server

- Number: 1

- Indication: Status LEDs: “Power,” “Failure,” and “Maintenance request”/ LC display

- Operation: Via LC display and membrane keyboard

- I/O module:

- Description: Closed module with top-hat rail adapter or module for integration into enclosures

- Analog outputs: 4 outputs, 0/2/4 … 20 mA, 500 Ω, Electrically isolated

- Analog inputs: 2 inputs, 0/4 … 20 mA, Not electrically isolated

- Digital outputs: 8 outputs, 34 V AC, 500 mA / 48 V DC, 500 mA

- Digital inputs: 8 inputs, 42 V, All inlets with common reference potential

Gas module

- Sample gas connections:

PVDF compression fitting: for hose 6 x 1 mm

Swagelok 6 mm: stainless steel, for metal tube

Swagelok 1/4″: stainless steel, for metal tube

- Options:

Magnetic piston pump (0 … 60 l/h at 100 hPa low pressure)

Humidity sensor

Pressure sensor (500 … 1500 hPa)

Flow sensor (0 … 100 l/h, ±20%)