- Input mA: -1 to +50 mA

- Input impedance: 10 Ω

- Adjustments – Zero: Any value within range limits

- Adjustments – Minimum spans: 0,4 mA

- Output: 4-20 / 20-4 mA

- Operating temperature: -20 to +70 °C / -4 to +158 °F

- Galvanic isolation: 1500 VAC, 1 min

- Power supply: 7,5 to 36 VDC

- Typical accuracy: ±0,1 % of span

- Mounting: DIN-rail acc. DIN EN50022, 35 mm

Isolators IPAQ-L(MA)

- Input mA: -1 to +50 mA

- Input impedance: 10 Ω

- Adjustments – Zero: Any value within range limits

- Adjustments – Minimum spans: 0,4 mA

- Output: 4-20 / 20-4 mA

- Galvanic isolation: 1500 VAC, 1 min

- Power supply: 7,5 to 36 VDC

- Typical accuracy: ±0,1 % of span

Category: Signal isolation

Tag: test

At a glance:

- IPAQ-L(mA) is an active isolation transmitter for mA input signals with a 4-20 mA output in a 2-wire connection. It is suitable for direct connection to the input modules of a control system.

- Thanks to the programmable input range and the low input impedance, IPAQ-L(mA) meets almost any need for current signal isolation and load amplification.

- Input: mA signal

- Programmable measuring range within -1 to +50 mA

- Output: 4-20 mA in 2-wire connection

- 1500 VAC isolation input/output

- Low input impedance

- Full access to all features while in operation

- Simplified loop check-up with calibration output

- Test output without breaking the loop

- IPRO, easy-to-use Windows configuration software

Technical data:

- Input mA: -1 to +50 mA

- Input impedance: 10 Ω

- Adjustments – Zero: Any value within range limits

- Adjustments – Minimum spans: 0,4 mA

- Output: 4-20 / 20-4 mA

- Operating temperature: -20 to +70 °C / -4 to +158 °F

- Galvanic isolation: 1500 VAC, 1 min

- Power supply: 7,5 to 36 VDC

- Typical accuracy: ±0,1 % of span

- Mounting: DIN-rail acc. DIN EN50022, 35 mm

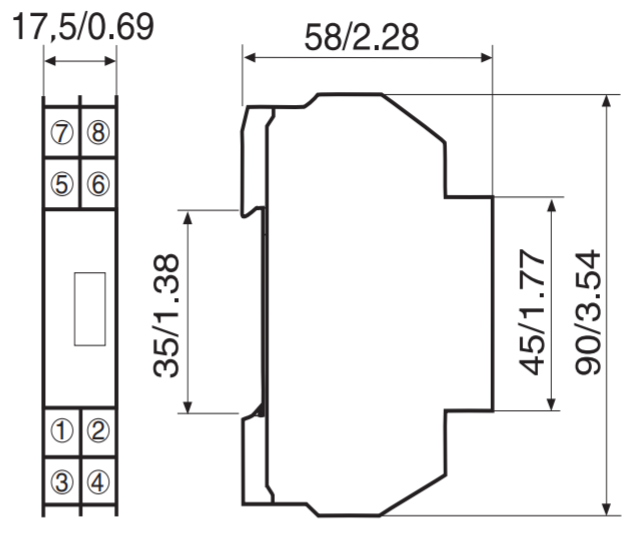

Dimensions:

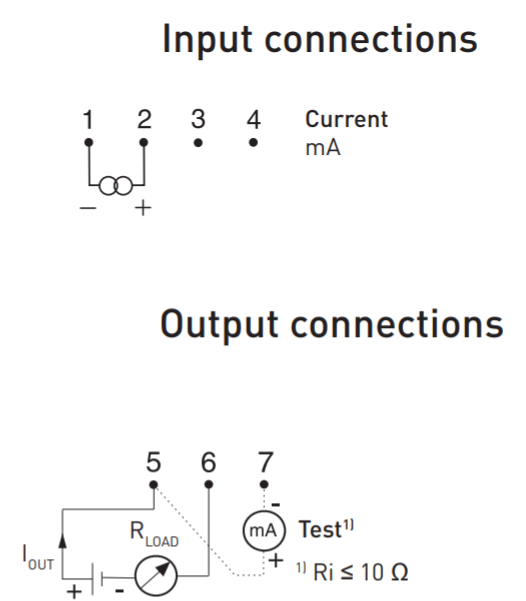

Connection diagram:

You can download more at the document here: Download

Related products

SALE

Signal isolation

- Type of input: Active

- No. of channels: 1 channel

- Input signal: 0…20 mA 4…20 mA 0…10 V

- Output signal: ±10 mA ±20 mA 0(2)…10 mA 0(4)…20 mA ±5 V ±10 V 0(1)…5 V 0(2)…10 V

- Typical accuracy: 0,1 % FS

- Isolation level: 4 kV, 50 Hz

- Power supply: 20…253 VAC/DC

- Cut-off frequency (-3 dB): 30 Hz/10 kHz switch select.

SALE

Scattered light dust Measuring Devices

- The DUSTHUNTER SP30 is a measuring device which reliably detects very low to high dust content

- Emission monitoring which does not require permission in industrial systems

- Dust concentration measurements in exhaust gas ducts

- Monitoring of cloth filters for defective filter bags

- Ideal for monitoring electrostatic precipitators

- Dust monitoring in grinding and dosing systems

- Monitoring and regulation of fresh air and exhaust air systems

SALE

Signal isolation

- The Bipolar Isolation Amplifier IisPAQ-661 is used for isolation and conversion of bipolar and unipolar industrial standard signals.

- Input Current (calibrated switchable): ±20 mA, 0… 20 mA, 4… 20 mA/ ±10 mA, 0… 10 mA, 2… 10 mA

- Input Voltage (calibrated switchable): ±10 V, 0… 10 V, 2 … 10 V/ ±5 V, 0… 5 V, 1 … 5 V

- Output Current (calibrated switchable): ±20 mA, 0… 20 mA, 4… 20 mA/ ±10 mA, 0… 10 mA, 2… 10 mA

- Output Voltage (calibrated switchable): ±10 V, 0… 10 V, 2 … 10 V / ±5 V, 0… 5 V, 1 … 5 V

SALE

Scattered light dust Measuring Devices

- Measurement independent of gas velocity, humidity and particle charge

- Approved according to EN 15267

- For medium to large duct diameters

- Emission monitoring of power stations and waste incineration plants

- Monitoring of dust concentrations downstream of filter plants

- Monitoring of dust loads in factory workshops

- Control of fresh air supplies and exhaust air plants

SALE

Fuel, Gas & Oil Valves

- Valve Actuation: Solenoid

- Body Material: Aluminum

- Media: Natural Gas

- The ASCO Series S261 is a line of solenoid valves designed for on-off control of fuel gas in commercial and industrial gas burners.

- Suitable for ambient temperatures up to 175°F