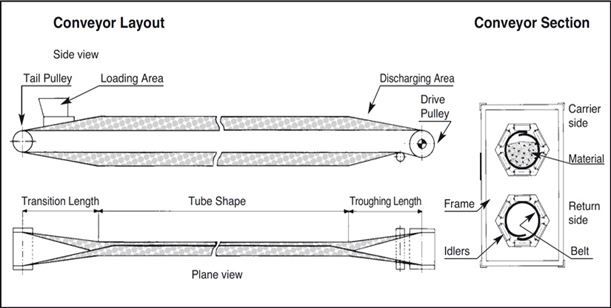

| Nominal tube |

Indicative belt width |

Standard idler spacing |

Minimum transition distance** |

Minimum curve radius** |

Max lump size |

Max speed |

Volumetric Capacity* |

| mm | mm | m | m | m | mm | m/sec | m3/h |

| 100

150 200 250 300 350 400 450 500 550 |

450

600 800 1000 1200 1400 1600 1800 1900 2100 |

1,10

1,10 1,30 1,45 1,60 2,00 2,20 2,30 2,40 2,50 |

2,5

4,0 5,0 6,5 7,5 9,5 10,0 11,0 12,5 13,5 |

30

45 60 75 90 105 120 135 150 165 |

33

45 60 75 95 110 125 140 160 180 |

2,2 2,2 2,5 2,5 3,0 3,5 4,0 4,5 5,0 5,5

|

21,2

46,9 84,7 132,4 190,7 256,2 339,1 429,2 530,0 641,2 |

* Capacity is intended at 1 m/sec with suggested 75% filling factor

**Datas valid only for Pipex textile belts; for Piflex steel carcass belts correct the datas according to the rules here below

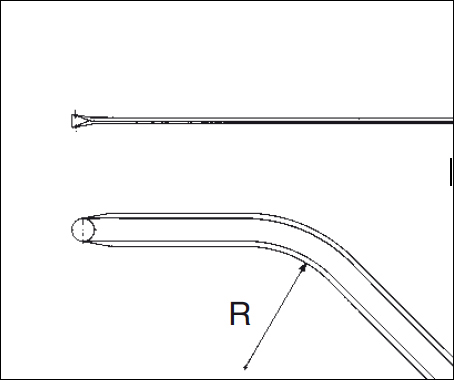

Maximum curve angle for standard applications ß1 ≤ 45°

Minimum radius admitted

R ≥ 300 x tube diameter for Pipex textile belts

R ≥ 600 x tube diameter for Piflex steel carcass belts

For angles > 45° minimum radius must be gradually increased till the double at the maximum allowed angle of 90°. Special belt construction must be considered in order to bear the lateral compression.

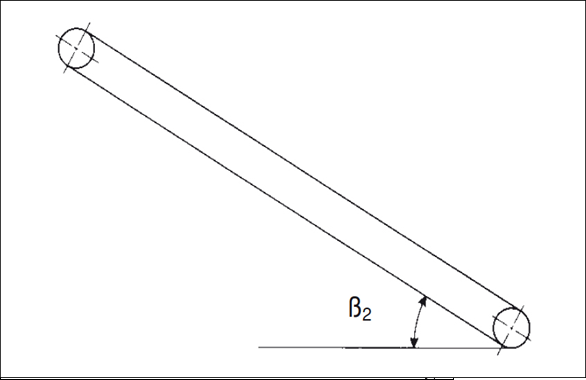

Max inclination ß2 = 30°

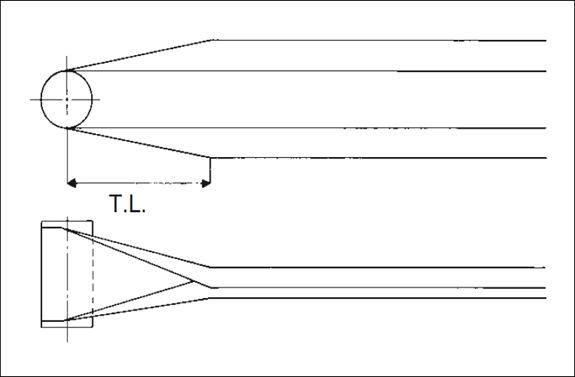

Minimum transition length

TL ≥ 25 x tube diameter for Pipex textile belts

TL ≥ 40 to 60 x tube diameter for Piflex steel carcass belts according to the elastic modulus