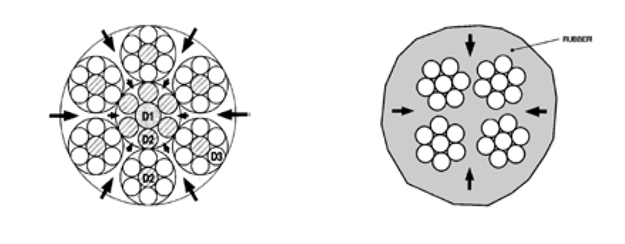

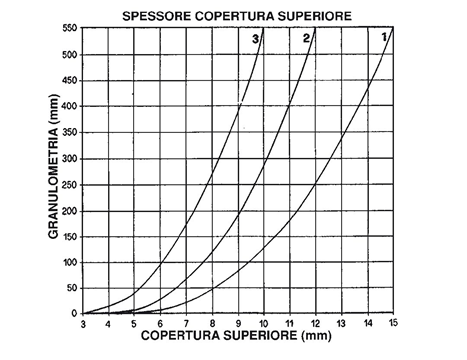

Cover Specifications

The main functions of rubber covers are the protection of the carcass against wear or damages during the running of the belt and the conveying of the material. The cover thickness required for a specific belt is in function of the material conveyed and of the handling method used. Thicker covers are required if the following conditions become more severe:

- Material abrasiveness

- Lump size

- Material sharpness

- Height of drop into the belt

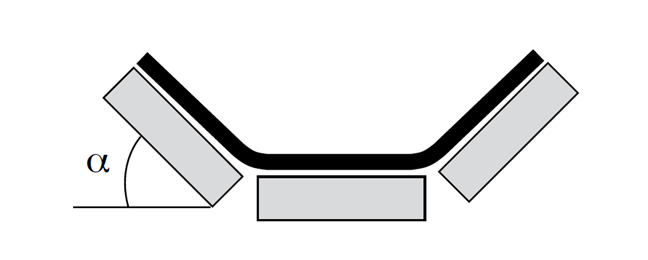

- Loading angle

- Belt speed and frequency of load

Here the suggested curves to estimate the correct cover thickness. Usually the bottom cover is half the top.

- – 1 = very hard cutting edge (e.g. granite)

- – 2 = angular, irregular (e.g. limestone)

- – 3 = rounded, light (e.g. charcoal)

ABRASION SERVICE

- CL Belts produced with this cover are recommended for all above ground applications where the resistance to abrasion is required. It is designed for the handling of heavy and abrasive materials such as gravel, crushed stones, sand, coal, cement, limestone, phosphate, salt, potash, etc. Grade L ISO 10247 – Grade Y DIN 22102 – RMA 2

- EC Belts produced with this particular compound are of superior quality expecially for abrasion . The characteristics of resistance against cut, tear, abrasion, ozone cracking, together with long duration, improve the quality of this cover. Grade D ISO 10247 – Grade W DIN 22102 – RMA1

HEAT RESISTANT

- CX This cover assures a medium degree of abrasion resistance and is formulated for continuous service of hot materials at temperature of 130 °C (270 °F) with peaks of up to 150 °C (300 °F). It is recommended for hot materials such as clinker, coke, hot scraps, fly ash, etc.

SELFEXTINGUISH

- BS This cover is designed to ser ve applications where safety is important and the fire risk is high. It is

- recommended for coal, potash, sulphure.

- According to ISO 340, ISO 284, DIN 22103, DIN 22104.

For special requirements please contact our commercial dept.