Công ty TNHH Thiết bị Công nghiệp và Tự động hóa AUMI – Đại lý phân phối chính thức sản phẩm hãng SICK tại Việt Nam

Từ năm 2008 Công ty TNHH Thiết bị Công nghiệp và Tự động hóa AUMI đã được ủy quyền trở thành Đại diện phân phối chính thức và duy nhất của hãng SICK trên toàn lãnh thổ Việt Nam.

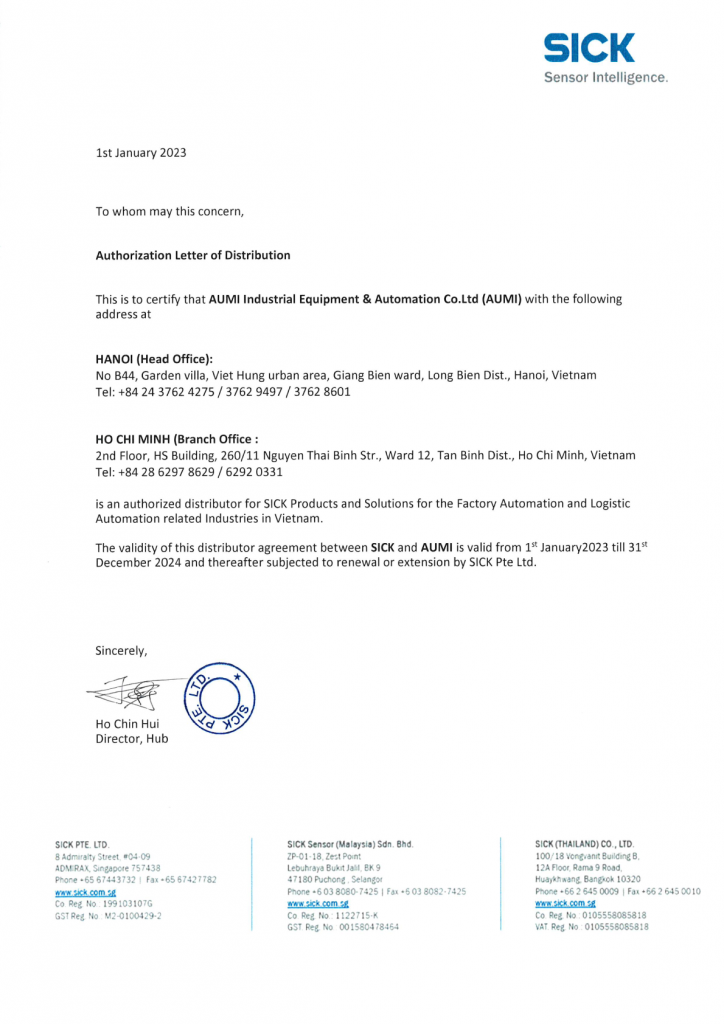

Dưới đây là THƯ ỦY QUYỀN HÃNG SICK CHO AUMI

Xin vui lòng tham chiếu theo đường link sau đây trên website hãng SICK: https://www.sick.com/sg/en/contact/worldwide

Tag: SICK Vietnam, SICK Sensor Vietnam, SICK Việt Nam, SICK Sensor Việt Nam